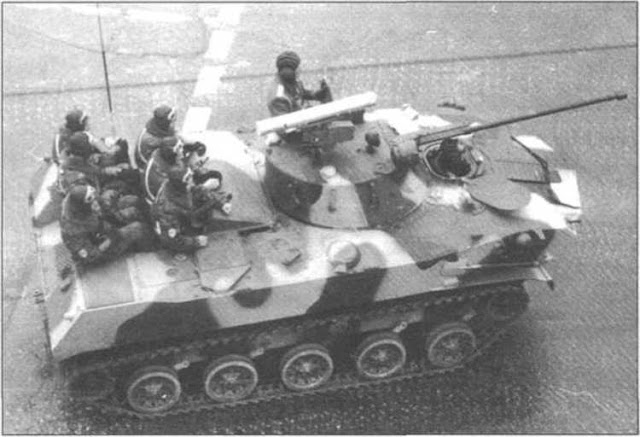

The BMD-2 is an airborne infantry fighting vehicle specially built for paradrop operations by the VDV - Russian airborne forces, first introduced in 1985. Its design is based on its predecessor, the BMD-1, which it is a modification of. Like the BMD-1, the BMD-2 belongs to a class of superlight IFVs designed with an emphasis on air transportability to increase the mechanized strength of airborne infantry. The turret had the same turret ring diameter of 1,380mm as the BMP-1 turret which was used on the BMD-1. As such, minimal modifications were needed to mount the new turret.

The BMD-2 never fully replaced the BMD-1, and it would seem that it was never intended to. The BMD-2's primary asset was its flexible 30mm autocannon, perfect for suppressive fire - and coupled with the high gun elevation made possible by the new turret and stabilizer system - a formidable threat to low-flying aircraft or infantry in elevated positions such as high rises or perhaps valley divides and mountains like in Afghanistan. However, there were things that the autocannon couldn't do that the 73mm cannon on the BMD-1 could. For instance, a single 73mm high-explosive shell is nearly 15 times more powerful than a 30mm equivalent, making it that much more useful for demolition work. Instead of replacing the BMD-1, the BMD-2 merely supplemented it, producing a synergy of sorts within the elite VDV.

COMMANDER'S STATION

The commander of the BMD-2 is situated in the front left hull. He is typically the squad leader or platoon leader of the infantry squad attached to the BMD, so he disembarks along with the rest of the passengers, leaving only the gunner and driver to operate alone. While operating from within the vehicle, he takes charge of one of the two bow machine guns. Unlike his neighbour bow machine gunner, though, he is supplied with an extra fixed periscope for additional situational awareness. But still, being located in the hull means that he is in a less elevated position than he would be had he been placed in the turret like on the BMP-2, the BMD-2's land-borne cousin. This, and the non-optimum observation devices means that he mostly concentrates on coordinating tactical maneuvers through his radio or relaying orders to the rest of the crew, but he doesn't spot or designate targets for the gunner as a tank commander usually does. The driver has better forward vision, so the commander doesn't need to navigate for the driver either. The value of the periscopes would be that they give the commander a sense of his surroundings to better understand where the vehicle is in relation to landmarks, platoon vehicles, etc.

Originally, the commander's station in the first BMD-2 models was exactly identical to the one from the BMD-1. He is provided with a single fixed TNPO-160 periscope aimed to the left and a single TNPP-220 rotatable sighting periscope, slaved to his bow machine gun.

The TNPP-220 periscope can be rotated and elevated or depressed only as far as the bow machine gun's arc of traverse. The periscope itself has total range of vision of 20 degrees in the vertical plane and 76 degrees in the horizontal plane, not accounting for traversal.

With just two periscopes and limited coverage, the commander's ability to assess the tactical situation was very severely handicapped. Later on though, the commander's bow machine gun was removed, and the periscope sighting device was replaced with an MK-4 periscope in a fully rotatable protective housing for better vision.

The MK-4S periscope can be rotated by a full 360 degrees, and elevated by +18 degrees and depressed by -12 degrees. The periscope grants him a net range of vision of 18 degrees in the vertical plane and 47 degrees in the horizontal plane. Unfortunately, the placement still hasn't changed. His vision will still be easily interfered with by tall grass, large rocks, shrubbery and other terrain features, and his vision suffers tremendously if the vehicle is on the move over rough ground. The commander can bear down on the handle of the periscope for some impromptu stabilization to partially relieve the problem.

The TNPO-160 periscope is a simple fixed periscope. It provides a total range of vision of 28 degrees in the vertical plane and 78 degrees in the horizontal plane. All periscopes are heated through the RTS electric heating system to prevent fogging in cold weather conditions, and the MK-4S periscope housing is also heated to prevent it from being frozen in place.

COMMUNITCATIONS

The R-123 FM radio station is located directly in front of the commander, beside the bow machine gun.

|

| Radio visible beside the driver's indicator panel |

The R-123 radio had a frequency range of between 20 MHZ to 51.5 MHZ. It could be tuned to any frequency within those limits via a knob, or the commander could switch between four preset frequencies for communications within a platoon (which takes 3 seconds). It had a range of between 16km to 50km. The R-123 had a novel glass prism window at the top of the apparatus that displayed the operating frequency. An internal bulb illuminated a dial, imposing it onto the prism where it is displayed. The R-123 had an advanced modular design that enabled it to be repaired quickly by simply swapping out individual modules.

In 1984, the now-outdated R-123 radio was replaced by the R-173 radio, which had a frequency range of between 30 MHZ to 75.999MHZ. It has 10 preset frequencies. It had an electronic keypad for entering the desired frequency, and a digital display.

|

| R-173 |

In the late 2000's, several hundred BMD-2s began a modernization program which included capital repairs and the installation of a new and advanced R-168-2UE-2 frequency-hopping encypted radio.

|

| R168-25UE-2 |

The R-168 family of radios is now standard throughout the Russian ground forces, from infantry platoons to tank companies. It can produce frequency hops 100 times a second, and the data is encrypted as well.

GUNNER'S STATION

The gunner is the sole occupant of the one-man turret. Because of the increased internal volume of the bigger turret, his station is less cramped than the one in a BMD-1, but it is still extremely cramped by any reasonable standard. In order to accommodate the gunner in the small turret, the 2A42 cannon was mounted slightly to the right of the turret while the gunner's seat was offset to the left.

The gunner has good all-round visibility from his station, which compensates for the lack of a commander in the turret. More importantly, it allows the gunner to independently spot and engage targets if the commander has dismounted the vehicle together with the other passengers. He is provided with four TNPO-160 periscopes, two aimed to the left and another two aimed to the right. Directly in front of him, of course, is where the gunsights are mounted. This is shown in the photo below.

In order to not interfere with the gunner's hatch, the two periscopes on the left side of the turret are installed in a special bulge. A cut was made into the round turret and a curved armour plate was welded on top of it, as shown in the photo below. The shape of the roof plate was designed with the bulge in mind, so the circular plate was stamped out with an irregular edge, as you can see in the photo above.

As mentioned before, the TNPO-160 provides a total range of vision of 28 degrees in the vertical plane and 78 degrees in the horizontal plane. Combined with the

He is provided with two sights; a combined day/night primary sight and a special high-elevation anti-aircraft sight.

|

| Note the larger combined primary sight on the turret roof and the smaller high elevation anti-aircraft sight to the right |

The weapons complex and fire control system is identical to the BMP-2. The weapons are controlled from a BU-25-2S control panel. The ammunition reserves for both the 2A42 cannon and the PKTM coax are shown on a small digital display, along with the ammunition type currently selected for the 2A42, and the gunner switches the ammunition type for the 2A42 by flicking a toggle switch.

At the back of the turret, on the roof, there is a small ventilation port which can be opened and closed from inside by the gunner. The cover is attached to a threaded guide rod, which has a handle at the bottom. The gunner simply turns the handle to screw guide rod down, lowering the cover and sealing the port hole. When it is closed, a rubber gasket prevents the ingress of contaminated particles from outside the vehicle, but also prevents the egress of gunpowder fumes from firing the 30mm cannon.

SIGHTING COMPLEXES

The BMD-2 mounts two sighting units - a BPK-2-42-01 transplanted from the BPK-2-42 sight that the BMP-2 uses, and a PZU-8 anti-aircraft sight.

|

| PZU-8 to the left, BPK-2-42-01 to the right |

BPK-2-42-01

The BPK-2-42-01 combined passive/active universal sight is the gunner's primary sight. It is a very slightly modified variant of the BMP-2's BPK-2-42 sight, practically identical in all respects. The sight is capable of passive light intensification or active imaging with the help of the L-2 Luna IR spotlight mounted coaxially to the gun and turret. The reticle may be illuminated by an internal light bulb to facilitate aiming at twilight hours if the night mode is not used. The nominal maximum range for identifying a tank-type target using active night vision is 800 meters.

The daytime sight channel has a fixed 6x magnification in the daytime channel and 5.5x in the nighttime channel, and a field of view of 10° in the daytime channel and the 6°40′ in the night channel.

The sight aperture is protected by a layer of ballistic glass to protect it from bomb splinters, but there is an additional spring-loaded pane of ballistic glass that may be lowered for protection from small arms fire. However, the supplementary pane has worse image clarity and could make reconnaissance a little bit harder, so it is usually kept raised unless explicitly needed. The sight has a small wiper.

The sight is an unremarkable one, unfurnished with any accurate method of rangefinding. To do that, the gunner must rely on a simple stadiametric scale with a maximum measuring distance of 2.5 km. Once the range to the target has been determined, the gunner must manually enter the range data into the sight, which then prompts it to make the necessary adjustments to the position of the reticle, namely, by raising the reticle up and down. The gunner must then manually lay the gun on the target by lining up the target with the adjusted reticle (which would be lowered to compensate for distance, forcing the gunner to raise the gun so that the reticle meets the target). This crude system is more commonly found on tanks from the 50's and 60's.

Overall, the process was slow and clumsy. Users probably preferred to depend on battlesighting, and walking the rounds onto target. This means that the reticle is fixed at a predetermined range, usually about a kilometer or so, and the gunner makes corrections on the fly depending on whether the shell went high or low. This cannot be considered advanced by any criteria, but it is some consolation that contemporary IFVs such as the M2A1 Bradley had to depend on a similarly clumsy stadiametric choke reticle for range finding.

SOZh-M

Recently modernized BMD-2 models have swapped out the BPK sight for the new and slightly more sophisticated SOZh accompanied by a new PL-1-01 laser beamer replacing the old IR spotlight.

By emitting a pulsed laser beam, the PL-1-01 can also double as a laser rangefinder. A pulsed beam also reduces backscatter in poor weather conditions, thus allowing the gunner to see farther.

At this point, only a limited number of BMD-2s have been confirmed to be modernized thusly. One example is known to have ended up in East Ukraine. The "silent modernization" of BMD-2s is likely to be ongoing as part of the general military modernization plan.

PZU-8

The PZU-8 sight is mounted on the side of the turret. It performs primarily in the anti-aircraft role, thanks to its extremely high elevation of +85° and depression of -10°. Its very large field of view of 50° enables the gunner to effectively track fixed wing ground attack aircraft as well as fast-moving attack helicopters. The sight lacks independent stabilization. It is directly linked mechanically to the cannon, so that it elevates and depresses with it.

|

| PZU-8 high-elevation auxiliary anti-aircraft sight. Notice the thickness of the steel protrusion protecting the sight along its length |

|

| Aperture |

STABILIZERS

2E36-1

The BMD-2 is provided with two-plane stabilization in the form of the 2E36-1 fully electromechanical stabilizer, including the EDM-30 electric motor for turret traverse and the DGN-3 electric motor drive for weapons elevation.

The 2E36-1 stabilization system uses electric motors for both horizontal and vertical drives. The preclusion of any hydraulic drives saves space and increases the safety factor enormously; the lack of flammable hydraulic fluid being pumped at high pressure greatly reduces the chance of a catastrophic internal fire in the event of a turret perforation.

|

| Vertical stabilizer motor and Horizontal stabilizer motor |

The 2E36-1 stabilizer system has two modes of operation; automatic and semi-automatic. In the automatic mode, the stabilizer operates in the traditional sense, obeying prompts from the gunner and keeping the turret and cannon oriented with maximal accuracy at a point determined by the gunner. The semi-automatic mode, however, only meant for anti-aircraft use. Once the cannon is elevated more than +35 degrees, the stabilizer system shifts into semi-automatic on its own accord. In this mode, the stabilizer disconnects from the BPK-2-42-01 sight, which cannot be used to aim at angles of elevation of above +35 degrees, and interfaces with the PZU-8 anti-aircraft sight. The stabilizer then loses some of its precision, but gains speed. This is to help track and engage fast, highly maneuverable attack helicopters strafing at low altitudes and at closer ranges, where the relative speed of the aircraft in question is higher than if it was many hundreds of meters away. At longer distances, the elevation angle necessary to engage an aircraft at a certain altitude is less than if the aircraft is closer and the relative speed of the aircraft is also lower, so turret rotation speed is less important but more precision is required. In that case the gunner may continue to make use of the stabilizer in the automatic mode.

The stabilizer is good enough for the job, though the turret traverse speed has the potential to be much higher. Modernized BMD-2Ms (the variant with Kornet launchers) are apparently equipped with the latest 2E36-6 stabilizer complex. How much the new system differs from the old one is not known at this time.

Automatic Mode

Time for full turret rotation: 12 seconds

Maximum Traversal Speed: 30°/sec

Minimum Traversal Speed: 0.07°/sec

Maximum Elevation Speed: 30°/sec

Minimum Elevation Speed: 0.07°/sec

With a minimum traverse and elevation speed of 0.07 degrees per second, the average accuracy of stabilization would be able to achieve an aiming precision of no less than 1.24 mils, which is equivalent to 1.24 meters at 1 km. With the accuracy of the armament itself accounted for, that degree of accuracy would be more than enough to guarantee consistent hits on targets of the APC and IFV variety at typical combat ranges, though the degree of precision is still very lacking compared to Western technological equivalents of the time.

Semi-Automatic Mode

Time for full turret rotation: 10 seconds

Minimum Traversal Speed: 0.1°/sec

Maximum Elevation Speed: 35°/sec

Minimum Elevation Speed: 0.1°/secAt a cruising speed of 25 km/h to 35 km/h, the stabilizer is capable of maintaining its orientation at or close to its best performance. Drifting is noticeable at higher speeds. Needless to say, the precision increases linearly as the speed of the vehicle decreases.

ARMAMENT

The primary weapons of the BMD-2 were a single 2A42 autocannon and a PKTM coaxial machine gun. The turret has provisions for mounting a 9M111 Fagot or 9M113 Konkurs ATGM on the roof to be fired by the gunner, who had to be partially exposed on the turret roof.

2A42

The 2A42 is a dual-feed autocannon chambered for the Soviet 30x165mm cartridge. It has a variable rate of fire of either 200 rounds per minute or 550 rounds per minute. However, it can go up to 800 rounds per minute once the cannon is heated up by a few seconds of firing on full auto. Its high rate of fire is invaluable during engagements with concentrations of infantry, or when attacking a well-fortified position, whereby extra demolition power may be necessary. In practice, the 2A42 is simply irreplaceable during engagements with stealthy adversaries. Even with thermal imaging sights, it may prove nigh impossible to spot and hit skilled and agile foot soldiers hidden in foliage and constantly on the move. Under such circumstances, the ability to saturate likely spots and areas of interest with high-explosive cannon shells is absolutely invaluable for preserving the vehicle itself as well act as in support of dismounted infantry. This was one of the reasons why the BMP-2 and BMD-2 was much more successful in Afghanistan and Chechnya than the BMP-1 and BMD-1.

The gun has +60 degrees of elevation and -5 degrees of depression. This gave the BMD-2 the ability to engage aircraft, as well as targets located in high rises and tall mountains, but the inability to adequately take advantage of reverse slopes remains constant. This is quite a blow to the overall survivability of the BMD-2, as its armour is far too thin to be able to sustain a head-on firefight, so it must always operate undercover. "Hull down" doesn't necessarily involve reverse slopes, of course. The BMD-2 can still take advantage of thick shrubbery, large rocks and other terrain features for concealment, but having one option denied to it is no small matter.

Maximum dispersion is 346.67mm at a distance of 100m. This figure can be expressed as 13.036 MOA (13.036 x 1.047 inches at 100 yards). This figure was calculated from an acceptance test video of the DVK-30 drop-in turret (link). By obtaining an MOA figure, which is an angular unit of dispersion, we can very easily find out what sort of dispersion we would get at different distances. At 1000 meters, the maximum dispersion (which I will define as the length of the distance between the two impacts that are furthest from each other), should be 3.467 meters, and all shots fire must invariably lie within that limit. Alternatively, a figure of ∼3 meters at a distance of 1000m can be expressed as a dispersion of 3 mils. This is congruent with claims floating around the internet of an accuracy of "2 - 4 mils". No doubt that this is pretty terrible performance for an autocannon firing at 200-300 rounds per minute, but that should be the maximum dispersion. The median dispersion should be much smaller. The second volley in the video shows a dispersion of just 8.12 MOA. That would be a dispersion of only 2.362 meters at a distance of 1000 m. Again, this fits into the "2 - 4 mils" claim neatly. The 2A42 cannon has a predisposition to create vertical shot groups. In both of the firing tests shown in the video, four rounds were arranged neatly in a vertical pattern, with one outlying shot skewing the results for the worst. As such, even though the cannon has an angular dispersion of 2 - 4 mils, 80% of the shots seem to tend to end up in an oval group of less than 2 meters.

This data should be valid for full caliber rounds like the 3BR6 and 3OF8. Subcaliber rounds like the 3BR8 will display superior accuracy and better consistency at all ranges, but the difference is only truly visible at longer ranges. 3BR8 APDS should have a maximum dispersion of 2 mils when fired from the 2A42, and just like with full caliber rounds, most of the shots will likely be located in an oval group less than 2 mils in size, as shot patterning depends more on the particular harmonic properties of the weapon system rather than the ammunition itself. However, it remains to be seen if the BMD-2 will have access to 3UBR8 rounds.

Although much less accurate than its immediate counterparts, the 2A42 cannon is more than capable of engaging pinpoint targets, though not as efficiently as the British RARDEN or American Mk44, which are more accurate by nearly two times. The RARDEN is accurate by virtue of special dampening and a very tame rate of fire, while the Mk44 is accurate thanks to a 69.4 kg barrel. If the gunner went for the RARDEN route and switched to semi-automatic to fire the cannon only about twice every second, it should be possible to approach (not meet) the same level of accuracy. Keeping in mind the fact that the ammunition capacity for the BMD-2 is quite limited, this is the only way the gunner can effectively eliminate armoured targets at long range while still having enough ammunition to complete the rest of the objective. In situations where accuracy may only have supplementary value, such as when engaging large concentrations of manpower, the 2A42 is at a clear advantage.

By virtue of its high rate of fire and powerful ammunition, the 2A42 is effective even against main battle tanks of the modern era, not to mention more lightly armoured vehicles. Live fire testing confirmed that the 2A42 is not only able to produce a 'mission kill' on main battle tanks, but also do it very rapidly, which is an invaluable attribute, especially for a vehicle as light as the BMD-2. In the space of a few seconds, the gunner can let off around 20 to 30 shots with a few short bursts at medium ranges and reliably guarantee the destruction or disablement of various exterior devices such as tracks, periscopes, sensors, weapons, or perhaps large exterior laser rangefinders and IR spotlights as found on 60's and 70's era tanks. After a few seconds of action, the BMD-2 can immediately disappear behind terrain under the cover of a smokescreen.

The autocannon is mounted slightly off to the right, which drives an unfortunate tendency for the turret to spin slightly to the right when the autocannon fires long bursts in full automatic. The effect is negligible at slower rates of fire, though, so this idiosyncrasy shouldn't affect accuracy too much when it matters. This problem possibly led to the use of the low-recoil 2A72 cannon in the BPPU-1 turret for the BTR-80A and the BTR-82A instead of the 2A42.

The ammunition load of 300 rounds is stowed in separate conformal containers on the right side of the turret, the space on the left side being reserved for the gunner. 180 rounds of HEI/-T ammunition and 120 rounds AP-T and APDS-T ammunition are available. Under certain mission conditions where encounters with armoured vehicles are not expected, both containers can be loaded purely with HEI/-T ammunition. This was not uncommonly done in low intensity conflicts such as in Chechnya or Afghanistan.

|

| The red container contains ready ammunition |

Although the autocannon is undoubtedly quite powerful, the small stock of ready ammunition carried in the BMD-2 severely limits the vehicle's ability to conduct sustained firefights, and the lack of internal space makes stowing additional ammunition troublesome. Compared to the German Marder 1A+ series, for example; those carry up to 1250 rounds of a much less lethal 20mm caliber, but that means that a Marder gunner has far more freedom in choosing his targets and a better ability to provide suppressive fire. Whether that suppressive fire actually has a chance of injuring anybody is a completely different question. 20x139mm HEI ammunition for the Marder's Rh202 autocannon packs a measly 5.8g of Hexal, and the projectile itself weighs 125g. Compare that to the 3UOF8, which presides in an entirely different category altogether:

There are three pyrotechnic charges that can be used to instantaneously cock the cannon and ready it for firing or to clear a malfunction during combat. Normally, the cannon is readied manually by the gunner by having its bolt mechanism puled back by using a ratcheted lever attached to the cannon receiver. The process is laborious and time consuming (due to the heavy recoil spring necessary to withstand the tremendous recoil forces), but it does have its own advantages. Although such eccentricities would not be necessary in an electrically operated chaingun, a chaingun requires external power to fire. If the power source was interrupted, a chaingun would be rendered useless. Due to its gas-powered nature, the 2A42 can still be fired with the BMD-2 operating in "degraded mode" where the engine is knocked out and battery power is cut off, so that all operations are reverted to manual control.

This page contains a detailed examination of each 30mm cartridge available to the BMD-2 during its brief service in the Soviet Army.

SECONDARY

A PKTM machine gun is mounted on the turret as a coaxial weapon, mainly for use in situations where the autocannon might be unnecessary or excessive for the task. Considering the relatively limited capacity of ammunition for the autocannon and the lack of a reserve supply, it may be sensible to use the PKTM for tasks such as engaging infantry behind light cover. As a rule, 7.62mm rifle rounds are not powerful enough to prove to be meaningful in any large capacity against entrenched manpower or infantry behind field fortifications. Ammunition is supplied in 250-round belts stored in individual boxes. This was a downgrade from the BMD-1 which held 2,000 rounds in a single box so the gunner would not be distracted by the need to reload the machine gun. The only advantage is that smaller boxes of 250 rounds tend to be less likely to cause stoppages, but since the one-man turret is only occupied by the gunner and he is responsible for everything inside it, giving him more responsibilities does not increase the combat effectiveness of the weapon system.

BOW MACHINE GUNS

Two more PKB machine guns are mounted on either side of the forward hull to be used by the two passengers seated on either side of the driver. Late model BMD-2s had the port side bow machine gun removed to free up more space for the commander to perform his other duties (manning the radio station, observing, etc). The unused machine gun port would be covered with an armoured plug.

The PKB machine gun was a modified PK machine gun with removable spade grips and modified trigger. The the rotating TNPP-220 periscope directly in front of the bow gunner(s) is mechanically slaved to the machine gun port. This meant that wherever the machine gun was pointed, the periscope would accurately face the same direction. Elevation as well as horizontal traverse were both fully accounted for. The bow gunner would aim using a small scope on the right side of the TNPP-220 periscope, visible below.

A small internal 1.5x scope is installed inside the periscope and the eyepiece is viewed through the prismatic glass block of the periscope. Fire correction is done simply by using the fixed reticle markings and by observing the fall of the tracers from the machine gun to determine the correct distance and deflection.

The aiming mechanism of the BMD-1 was carried over to the BMD-2. As you can see in the two pictures below, the TNPP-220 periscope was mechanically linked to the ball turret by a pair of hinges. Traversing and elevating the bow machine gun would translate into the movement of the periscope. Because the periscope is placed directly above the machine gun, the horizontal parallax is negligible when aiming forward. However, when the machine gun is traversed or elevated, parallax in both axes increases.

Ammunition for the PKBs is supplied in 250-round belts in individual boxes. Although the aiming system is somewhat rudimentary from an technical point of view, it was quite useful and certainly quite novel. The spade grips and periscope combination probably allowed the bow gunner to hold the machine gun somewhat steady and provide reasonably accurate fire even while the vehicle is on the move.

The bow gunner's periscope and the ball turret for the machine gun are both heated. Heating for the periscope prevents fogging, and heating for the ball turret prevents it from freezing in place in icy weather. The mounting cradle for the PKTM machine gun is seen below.

|

| The periscope-to-machine gun connection has been dismantled in this example |

Additionally, there are two firing ports on either side of the hull.

|

| Firing port on the starboard hull |

|

| Firing port on the rear exit hatch |

The firing ports can fit any type of rifle.

TERTIARY

Like the BMD-1P preceding it, the BMD-2 features a small protruding post on the roof of the turret, on which the 9M111 Fagot or 9M113 Konkurs ATGM systems may be mounted. The BMD-2 was issued with 9P135 Konkurs missile launchers, which were backwards compatible with Fagot missiles.

It must be said outright that one of the biggest failings of the BMD-2 lies in the fact that this rooftop ATGM may only be fired by either a dismounted passenger manning it from behind the turret, or by the gunner, who must open his hatch. The whole process from aiming and firing the ATGM to guiding it to its target may take as much as 20 seconds, exposing the user to return fire all the while. Although the operator (usually the gunner) may not have much to fear from bullets coming from the front, as his 6mm-thick hatch offers some protection, he would be in danger from overhead threats like airbursting mortar shells and bomb splinters from all around him.

As mentioned earlier, the missile launcher itself is the standard 9P135 launch-and-control unit, sans tripod. The launcher is placed very high up relative to the turret, far above even the gunsights. A cunning crew could take advantage of this and park their BMD-2 behind a hill, exposing only the missile launcher. After hitting the target, the variable height suspension may be lowered to conceal the launcher for a reload, and raised for another shot.

Another distinct, if questionable advantage to this setup is that the missile launcher can be dismounted and used by the crew when fighting on foot, if perhaps the vehicle is disabled. This means that even if they are forced to abandon ship, the crew still has heavy weapons on hand and still can repel an attack, and perhaps even live to put the launcher back on its pedestal.

Both the Fagot and Konkurs missiles are wire-guided, utilizing an infrared bulb at the rear end of the rocket for the launcher to track, and both missiles are launched via a two-staged propulsion system. The first stage is a squib cartridge in the rear of the container which generates high-pressure gas that propels the missile out of the tube. Once the missile has cleared some distance, the rocket motor activates and sustains the missile's flight up until it has reached its target. The high magnification power of 10x offered by the 9P135 launcher enables the gunner to use the long range of the missile to its full extent.

Like with the BMP-2, the high placement of the missile launcher plus the height adjustment feature of the BMD-2 presents some unique tactical opportunities. For example, it is possible for the BMD-2 to be placed in complete defilade with the hull and turret behind a hill, rock or other type of cover or concealment, and have the ATGM fired over it. The vehicle can adapt to a variety of such pieces of cover expressly due to its height adjustment feature.

There can be a total of 3 missiles stored behind the gunner's seat. Reloading the missile launcher is slow and laborious due to the rather cramped nature of the turret, but the fact that the missiles are stowed inside the turret itself and not in the hull simplifies matters considerably. The average rate of fire should be around 2 rounds per minute with both the Fagot and Konkurs.

PROTECTION

The aluminium hull of the BMD-2 is carried over from the BMD-1, and the turret is made of steel, just like with its predecessor. The vehicle is very light, but that is not to say that the vehicle has distinguishably poor protection per se; Although the BMD-2 is much lighter than most other IFVs, it is also much, much smaller than most other IFVs, which means that it retains armour density roughly equal to that of a volumetrically larger and correspondingly heavier vehicle.

The hull is made of aluminium alloy, while the turret is made of steel. The frontal arc can withstand .50 caliber machine gun fire at point blank range but the side armour can only resist 7.62mm machine gun fire from several hundred meters - worse than the non-airborne BMP-2, but comparable to the M113, a similarly aluminium-cladded armour personnel carrier. The rolled aluminium alloy plates used in the BMD-2 is ABT-101, same as the BMD-1.

Contrary to the Wikipedia-perpetuated urban legend of the BMD-2 and BMD-1 having "cast magnesium armour" that "burned fiercely when hit by an RPG", neither the BMD-2 or the BMD-1 used cast magnesium armour. ABT-101 is an aluminium alloy for fabricating rolled plates, and both the BMD-1 and BMD-2 are built from welded plates. ABT-101 is an Al-Zn-Mg alloy containing 91% aluminium, while the other 9% is composed of zinc and magnesium, but mostly zinc. The rumours of "magnesium armour" being responsible for burning BMDs are likely based on burnt-out wrecks with melted hulls and wheels, but this has nothing to do with the magnesium content in the armour, but rather the low melting point of aluminium (only 591-638°C for 5083 alloy) which is almost a three times lower than armour grade steel, and low enough that ammunition and fuel fires can melt it when heated for prolonged periods. However, the aluminium itself does not burn so external heat must be applied constantly. The amount of heat measured in armour plating after penetration by a medium caliber shaped charge warhead (around 81mm) is only around 500°C. This is not only lower than the melting point of aluminium, but the heat is only applied in a few microseconds so it is too brief to actually melt the armour.

According to several research papers written on the subject, the effectiveness of the best aluminium armour and aluminium laminate armours may reach up to 50% of steel by thickness, but non-armour grade aluminium alloys are typically only around 40% as effective (or less). An example of this would be 5083 alloy, used in the M113. 5083 alloy was only 34% as effective as steel for the same thickness.

ABT-101 was specially developed to be used as armour, and because of that, it had more suitable properties, giving it significantly better performance - up to 45% as effective as steel armour per thickness. However, because of the generally worse hardness of aluminium, it is much less capable of deflecting ballistic threats than typical armour-grade steel for the same thickness, so aluminium armour does not gain as much protection from angling as hard, armour-grade steel would. ABT-101 has a hardness of approximately 145 BHN, harder than mild steel and harder than 7039 aluminium alloy, which is known to be used in American designs like the M551 Sheridan and M2 Bradley, and much, much harder than the 5083 alloy, which had a hardness of just 75 BHN. However, all of these aluminium alloys are much softer than typical RHA steel, which typically ranges from 220 BHN to 300 BHN in hardness. The comparatively greater hardness affords the BMD-2 better performance against bullets of all types compared to foreign aluminium armour, and certainly significantly greater potential as sloped armour.

The turret is made from welded hard steel plates. The front is uniformly 22mm thick, sloped at 37 degrees. This is enough for .50 caliber AP bullets at point blank range, but not much more. The rear of the turret is around 10mm thick.

The frontal hull aspect draws a great deal of its protection value from its pike-nosed geometry and heavy angling, best seen here:

The upper glacis is angled at 75 degrees on the vertical axis, and the lower glacis at 47 degrees. There is also an additional 20 degrees of horizontal sloping for both upper and lower glaces, creating a pike nose shape that is usually associated with Soviet heavy tanks. According to the compound angle table published in page 47 of World War II Ballistics: Armor and Gunnery, the compound angle of the upper and lower glacis plates will be 76 degrees and 50 degrees respectively. The upper glacis is 15mm thick while the lower glacis is 32mm thick. The line of sight (LOS) thickness of the upper glacis and lower glacis is therefore 62mm and 50mm respectively which is very impressive for such a light vehicle. The pure armour thickness is important, but not as important as the large compound angle which makes it very difficult for an uncapped ogive penetrator (as found in a typical Spitzer bullet) to not ricochet immediately without so much as denting the armour.

The sides are quite thin. The upper side plate is only 23mm thick, and the lower side plate is thinner at just 20mm. The roof of the hull is not enough to resist large caliber airbursting artillery shells. Based on testing with 7.62mm and 12.7mm steel-cored AP-I bullets, 23mm of ABT-101 is equivalent to 10.35mm of RHA. In terms of effective thickness, the side armour is nominally equivalent to the BTR-60 and MT-LB.

To better appreciate the protection offered by the angles of the frontal armour, we can take a look at the phase diagram below. This phase diagram, taken from Armour: Materials, Theory, and Design, illustrates the huge importance of slope. As you can see, the test used a 6.35 mm aluminium alloy plate - no doubt 5083 aluminium - as a target, and 6.35 mm-diameter solid steel bullets as projectiles. A 6.35 mm projectile like this is representative of the steel AP core of the average 7.62mm rifle bullet. The AP core of a 7.62x54mm Russian B-32 bullet, for instance, has a diameter of 6.1 mm, with a weight of 5.39 grams. It has a muzzle velocity of 830 m/s. The AP core of a .30-06 M2 AP bullet has a diameter of 6.2 mm, and weighs 5.17 grams. It has a muzzle velocity of 855 m/s. The AP core of a 7.62x51mm M61 bullet has a diameter of 6.3 mm, and weighs 3.8 grams. It has a muzzle velocity of 838 m/s.

As you can see in the diagram, the thin aluminium plate is not thick enough to deflect the bullet at point blank range (muzzle velocity: 830-855 m/s) unless it is sloped at an angle of at least 65 degrees, whereupon the bullet will shatter against the plate and ricochet off harmlessly. The aluminium armour of the BMD-2 is never as thin as 6.35mm and the armour is not made from 5083 alloy so the findings above cannot be applied directly to the armour scheme on the vehicle. But still, it is an interesting example of the importance of obliquity, as it demonstrates that a 75 BHN metal plate of rather low strength is capable of deflecting a bullet that matches it in thickness given that the angle of impact is sufficiently high. The test may or may not be scalable, but if it is, and we substitute the 7.62mm AP bullet with a .50 cal or 12.7mm one, we see that the upper glacis of the BMD-2 with its thickness of 15mm and compound slope of 76 is more than enough to deflect heavy machine gun fire at point blank range as the thickness of the plate is greater than the diameter of a .50 cal M2 AP bullet core and the obliquity is extremely high, while the 840 m/s muzzle velocity of the bullet from an M2 Browning is in the same range as typical 7.62mm rifle rounds. As it turns out, this speculation is confirmed by testing that found that the front of the BMD-1 is indeed immune to 12.7mm B-32 from point blank range. The lower glacis plate is not thicker than the upper glacis despite the greater physical thickness and the compound angle of the slope is also less at only 50 degrees, so in theory it is more vulnerable, but again, testing found that the front was immune to 12.7mm B-32 rounds.

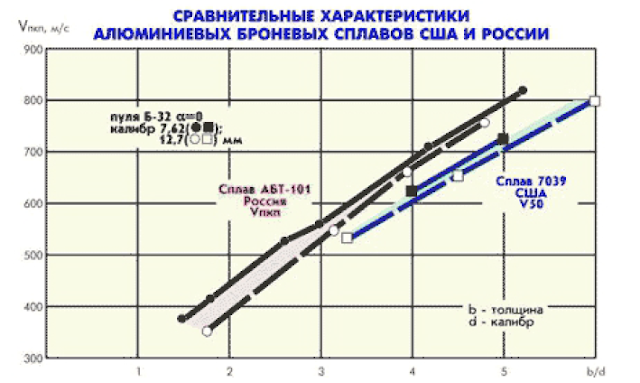

NII Stali has released some documentation on the ballistic performance tests of ABT-101 alloy. The graph below, titled "Comparative Characteristics of Aluminium Alloy Armour of the U.S.A and Russia", shows the thickness of the armour plate required to stop each bullet, quantified in terms of bullet diameter.

Legend: Bullet B-32 (Russian), Caliber: 7.62, 12.7

y-axis: Velocity (V)

x-axis: Armour thickness/Bullet caliber ratio

For reference: a 12.7mm B-32 bullet has a muzzle velocity of around 850 m/s when fired out of an NSV heavy machine gun, and a 7.62mm B-32 bullet has a muzzle velocity of 855 m/s when fired out of a PKM general purpose machine gun. Keep in mind that information for both the 5083 and 7039 alloys indicates that they are more efficient against 12.7mm bullets than 7.62mm bullets by weight compared to RHA steel.

Reading this graph, it appears that to stop a 7.62x54mm B-32 armour piercing bullet at a distance of 100 meters or so, it would take an ABT-101 armour plate with a thickness of around 4.2 calibers, which is 32mm. To stop the same bullet at a distance of 460 meters, it would take a plate with a thickness of 3 calibers, which will be 22.9mm - the same as the thickness of the upper side plate of a BMD-2. However, this does not necessarily mean that the side of a BMD-2 is badly protected from machine gun fire because NATO standardized on the 7.62x51mm cartridge during the 50's. The standard M61 steel-cored armour piercing bullet in the 7.62x51mm caliber is much less potent than .30-06 M2 AP and 7.62x54mm B-32, so the side armour of the vehicle still provides comprehensive protection against machine guns fielded by contemporary NATO armies.

Ballistic tests were conducted on the BMD-1 throughout its developmental cycle, and continued even after it formally entered service. During tests undertaken from October 25 to December 25 in 1972, the BMD-1 was subjected to more ballistic tests involving weapons ranging from 7.62x39mm ball bullets to 23mm hardened steel core armour piercing rounds. The black and white photos above and below show the state of the BMD-1 after the tests. These photos were taken from the December issue of Tekhnika i Vooruzhenie 2009.

The upper part of the side hull is proofed against 7.62x39mm BZ rounds at a distance of 125 meters, and the lower part is proofed at 175 meters. The front hull and turret are totally immune to 23mm BZT rounds (API-T) from a distance of 500 meters when shot from a frontal arc. If the firing range for 23mm BZT is decreased to 100 meters, the protected frontal arc shrinks to 28 degrees. 23mm BZT penetrates 24mm of RHA plate at 0 degrees at 500 meters, 15mm at 30 degrees at 700 m, 19mm at 0 degrees at 1000 m, and 10mm at 30 degrees at 1200 m. The table below lists the angle of immunity from four different types of small arms ammunition at point blank range.

| Ammunition | Angle of immunity (°), immunity arc (°) |

| 12.7x108mm B-32 (AP, hardened steel core) | 35, 70 |

| 7.62x54mm B-32 (AP, hardened steel core) | 53, 106 |

| 7.62x54mm Light Ball (FMJ, mild steel core) | 70, 140 |

| 7.62x39mm BZ (AP-I, hardened steel core incendiary) | 68, 136 |

Based on the information that a frontal arc is immune to 23mm BZT rounds from 500 meters, the frontal arc of immunity from that distance should be 54 degrees. During the course of the testing, it was discovered that the amount of protection afforded to the radiator packs (the two humps on either side, above the rectangular exhaust ports) from gunfire was unsatisfactory, but the sloped engine cover panel (see photo below) was heavy enough to deflect 7.62x39mm BZ rounds fired from a distance of 125 meters.

The diminutive size of the BMD-2 contributes greatly to its overall survivability. With maximum ground clearance, the BMD-2 is negligibly taller than the average Soviet male combatant at 1.905m, but only 1.585m tall with minimal ground clearance. The photo below perfectly illustrates the low height of the BMD-2 at the maximum suspension height.

Because of its small profile, it is exceptionally difficult to reliably score hits on the vehicle at long distances with machine guns using only the iron sights. Attempting to visually identify a camouflaged BMD-2 from afar would also be a challenge, especially when plenty of shrubbery is present and the crew is properly taking advantage of terrain features with the help of the vehicle's variable ground clearance. Thus, although the armour of the BMD-2 is wholly insufficient against serious anti-armour weapons, its survivability would still be quite high.

However, the advantage of small size has been greatly diminished in the present. Current generation autocannons like the new Rheinmetall Mk30-2/ABM and Bushmaster Mk44 are so accurate when paired with modern fire control systems that they will have no trouble at all achieving a near-100% hit rate at long distances on the BMD-2, even while both the weapon platform and target are on the move. Modern thermal imaging sights will be able to see and track the BMD-2 as clear as day at any distance except when the BMD-2 is operating in a hull down position.

ERGONOMICS

It should come as no surprise that the small size of the BMD-2 entails cramped conditions inside the passenger compartment. There are three seats immediately behind the turret basket for dismounts, arranged around the circumference of the turret. Two are located on either corners of the compartment and the center seat is located directly underneath the large exit hatch, but there is so little distance between the turret basket and the engine compartment partition that the dismount must sit sideways on this center seat.

|

| Port side passenger's seat |

|

| Center passenger's seat |

The interior is very cramped in general. There is barely enough room for the squad to haul along additional equipment other than a RPG-16 or RPG-7D. The fender shelves (empty space of the hull above the tracks) can be used to stow a MANPADS launcher.

Each seat is provided with a periscope to grant the occupants some situational awareness. The two passengers seated on either side of the hull are given a TNPO-160 periscope each, which are aimed slightly forward. There is another MK-4 rotatable periscope mounted in the rear hatch, which allows excellent coverage of the vehicle's rear and flanks. This periscope lets the passenger seated at the center seat to direct the driver when reversing.

Ventilation for all occupants is provided by a single dome-shaped ventilator located on the starboard side of the hull, adjacent to the turret.

The ventilator sucks in air through a wire mesh-covered radial port. It has an internal filter for operation in highly dusty or chemically and biologically contaminated zones, and the filter additionally incorporates an integrated self-cleaning system, utilizing blasts of high pressure air to blow dust and other filtrates out through the evacuation port (protruding port on the dome, not covered by mesh, as seen above). This ventilator is responsible for creating an overpressure to prevent any such contaminants from entering the vehicle.

The ventilator has an electric heater installed for supplying the occupants with warm air during the winter. There are two storage bins located on top of the engine deck. They are meant for tools and spare parts. The location of the bins practically guarantees that they will be untouched during combat.

DRIVER-MECHANIC'S STATION

At the very front of the hull is the driver's station. The steering system is of a tiller-type, with dry friction clutches. The tillers also connected to a pulley system, which opens and closes the water jet covers depending on how far the tillers are pulled back. He has access to all the necessary driving-related controls as well as controls for all of the miscellaneous features of the vehicle, including interior heating, NBC activation, and the like. The instrument panel can be seen in the photo below. Note that the absolute maximum speed is 100 km/h.

The driver has very good driving visibility from his bank of three TNPO-160A periscopes. They are heated through the RTC system to prevent fogging.

The center periscope may be replaced with a binocular night vision periscope.

Or a TNP-370A extended periscope for when the vehicle is swimming.

The BMD-2 has a single F-125 IR headlight on the starboard side and a single F-126 white light headlight on the port side. The F-127 IR periscope is used exclusively in tandem with the binocular night vision periscope for nighttime driving. The view range of the periscope is completely insufficient for any real navigation, but it is good enough for road marches and less intense maneuvering. The IR filter cap may be removed to revert the IR headlight into a regular driving light if needed.

|

| Starboard side driving light and of course, the horn |

For convoy driving, the F-126 headlight/blackout light may be used. Blackout lights function by directing light forwards and downwards through small slits, minimizing the amount of light being transmitted off in other directions. This is to minimize the possibility of being seen, especially from afar. Because blackout lights only illuminate very small areas in front of the vehicle, the driver can't really see any further than a few meters. Depending on them for navigation is completely out of the question.

MOBILITY

Both the BMD-1 and the BMD-2 are powered by the low-profile 5D-20 V-shaped 6-cylinder diesel engine, located at the rear of the hull. It produces 240 hp at 2400 RPM. Originally, there were three methods to start the engine; electrically, pneumatically and combined. The pneumatic method involved using compressed air from a 10-liter compressed air tank to get the pistons moving, while the electric method required the use of the S-5 15 hp electric starter motor. The combined method is, obviously, a combination of the two. The combination method is most useful in cold weather. In 1973, the BMD-1 received the AK-150MKV air compressor. AK-150MKV was powered by the engine via a reduction gear through the gearbox. The introduction of this air compressor enabled the BMD to refill its 10-liter compressed air tank on the move, thus making it possible to rely entirely on the pneumatic starting system for every occasion.

The BMD-2 is heavier than the BMD-1, but it is still an extremely light combat vehicle at only 8 tons empty, and 8.225 tons fully combat loaded. The power to weight ratio is 29.2 hp/ton when combat loaded, and over 30 hp/ton when not. This is slightly lower than the BMD-1, but still good for its class of vehicle. For context, the BMD-1 is lighter, just 6.7 tons empty. According to the manual, the BMD-1P weighs 6.7 tons empty, 7.2 tons with fuel and oil, and 7.38 tons fully loaded for combat. The power to weight ratio is 32.5 hp/ton when fully loaded, and the average ground pressure exerted is 7.1 psi.

Both the BMD-1 and BMD-2 have a maximum driving speed of 61 km/h on a highway, and an average speed of 30 to 50 km/h when travelling cross country. It readily accelerates, and the amount of torque generated lets the vehicle traverse rough terrain speedily.

The engine is liquid-cooled. The radiator is located to the left side of the engine compartment. The photo below shows the engine air intake.

Located immediately behind the engine is the transmission. The drive shaft that spins the engine air intake fan is the same shaft that connects to the gearbox.

The exhausts are located at the two rearmost corners of the hull. The radiators are located on the top of either side of the two "humps", above the exhaust ports, and above the fuel and oil tanks.

Take a look at the photo below. Notice the pipes from the manifolds of the engine leading out towards the exhausts.

As mentioned before, the radiators are protected by armoured louvers which can be remotely shut by the driver from his station. They are supposed to provide protection from airbursting shells, small arms fire from above and flame attacks, but seeing how thin the roof of the hull of the vehicle is, there is no real point in taking this step.

There is an integrated electric heater to heat up air before it enters the engine, to facilitate starting in cold weather.

The BMD-2 can climb a vertical slope of 32 degrees, traverse a side slope of 18 degrees, and overcome a vertical obstacle 0.7m in height. It is able to cross trenches 2.5m in width, but is is capable of leaping over gaps as wide as 4m or more by running on a ramp or hitting a bump just before crossing. The BMD-2 can this do effortlessly and almost without risk thanks to its ability to get itself up to a very high speed.

The BMD-2 has five solid die-cast aluminium roadwheels with rubber rims on either side. Lightweight hollow roadwheels like the type used in the BMP-1 and BMP-2 helped increase buoyancy, but they would not have been able to withstand the force of an airdrop landing, thus necessitating roadwheels exclusive to the BMD-1 and BMD-2. Despite this, the lightness of the chassis and the relative softness of aluminium compared to steel means that the overall resilience of the suspension to high dynamic loads and hard impacts is quite low. A collision with a tree will result in a ripped-off idler wheel and roadwheel.

The BMD-2 has a ground pressure of 7.1 psi fully loaded, which is rather high despite its low weight. This is because of its thin tracks, which are also unfortunately somewhat fragile. The thinness of the tracks means that there is less frictional force with the ground (not the same as traction) when turning. This gives it superb agility over paved roads as well as dirt ones, but the BMD-2 suffers when crossing swampy ground. In which case, it must make good use of the eponymous log. The BMD-2's performance is snowy terrain is excellent. The relatively high ground pressure enables the tracks to penetrate snow and reach the frozen soil underneath, thus granting the BMD-2 good traction.

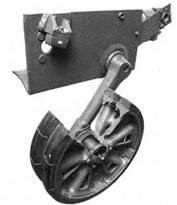

The innovative hydropneumatic suspension on the BMD-2 carries over from the BMD-1. It is very compact. The unique suspension gives the BMD-2 the ability to adjust ground clearance on-the-fly. The ground clearance can be adjusted to either 0.1m or 0.45m, or anything in between. The default setting for driving is 0.42m. The lowest setting is used to properly load the BMD-2 onto a plane before an air drop to minimize impulsive forces on the suspension in order to prevent damage to the suspension upon landing, but it is also useful for reducing the total height of the vehicle to let it fit better into the confines of a cargo hold. This is contrary to counterparts like the Bradley, which must be lashed to a loading pallet with tremendous force to compress the torsion bar suspension so that the hull would be as low as possible for loading. With the BMD-2, all this is done at the flick of a switch by the driver. The vehicle may be driven in any configuration. Fully lowered, the roadwheels have almost no room to travel and therefore cannot absorb shocks from terrain irregularities.

|

| Lowered, not tensioned |

|

| Raised |

The hydropneumatic mechanism is visible in the photo above. It is currently disconnected from roadwheel arm (you can even see the locking pin on the floor). The BMD in the photo must be resting on the belly of the hull, judging from the position of the roadwheel arm.

Air for the pneumatic springs is supplied by an air compressor powered by the engine. It is located directly forward of the engine, behind the partition between the engine compartment with the passenger compartment.

And of course, the idler wheel and drive sprocket can be adjusted for track tension as well. This is done by a hydraulic piston.

The tracks on the BMD-1 are of the single pin variety with rectangular inner guide horns, as you can see below:

The BMD-1P introduced new tracks with "dog bone" guide horns. These tracks are thicker and sturdier, but also slightly heavier. They are harder to throw and are just a bit better overall.

The new BMD-1P tracks carried over to the BMD-2.

FUEL

The BMD-2 holds a total of 280 liters of fuel in three separate tanks at the rear of the hull on either side of the engine compartment, giving it a maximum cruising range of 500 km on a highway on internal fuel alone. Because of the location of the fuel tanks, they will never pose a threat to the crew or the vehicle itself during combat. From the rear, they are hidden by the radiator and exhaust, completely precluding the possibility of them getting damaged by shrapnel or machine gun fire. If the sponsons were penetrated from the sides, fuel would simply leak out onto the ground harmlessly, away from the exit hatch at the engine deck. This gives the crew a chance to safely evacuate without being burnt.

According to the table below, the nominal fuel consumption of the 5D-20 engine is 0.8 liters per kilometer. The rate of fuel consumption is 72-85 liters per 100 km traveled on dirt roads, and 60 liters per 100 km traveled on paved roads, while the hourly fuel consumption rate is 25-30 liters on a dirt road and 23-25 liters on a paved road, or 40 liters per hour when swimming. With a full load of fuel, the BMD-2 can travel around 280-350 km on a dirt road or 450-500 km on a paved road. The vehicle swim continuously for 7 hours.

The table is taken from "Эксплуатация Многоцелевых Машин Контроль Технического Состояния И Техническое Обслуживание Боевой Машины Десантной БМД (БТР-Д), 2015", or, "Operation of Multipurpose Machines Monitoring of Technical Condition And Technical Maintenance of Combat Vehicle Landing BMD (BTR-D)", published by the Ministry of Defence of Russia in 2015.

To increase the range and autonomy of the vehicle when operating far ahead of the main force, an additional fuel tank is often included as standard equipment.

It is a fender fuel tank from a T-54 with a capacity of 95 liters. It is not connected to the fuel system, so the crew must manually siphon diesel from the external tank into the internal fuel tanks, which isn't very difficult since the fuel filler port is just next to where the external fuel tank is typically mounted.

WATER OBSTACLES

The BMD-2 is fully amphibious, and can readily enter and cross large bodies of water. But first, the driver must activate the electric bilge pumps (which throw water out of the interior if it is flooded), erect the wave breaker, and shut off the engine air intakes. All this is done automatically by flicking toggle switches. Like the BMD-1, the BMD-2 is propelled by two waterjets (pictured) when in the water.

To prevent water from sloshing up to the driver's hatch a trim vane must be erected. There is also a simple ribbed wave breaker attached to the hull glacis.

It is pushed up to the 'open' position by a small rod and crossbar assembly, pictured below:

|

| Wave breaker and trim vane removed |

Because the exhaust ports will be totally submerged when the BMD-2 enters water, the exhaust gasses are blown out by compressed air generated by the bilge pumps. The bilge pumps also work to throw water out of the hull through the same exhaust ports. This is done strongly enough to blow water straight up in the air.

When the vehicle exits water, the exhaust ports will spit any collected water back out with tremendous force as long as the bilge pumps are still on.

(The radiator is smoking, which never happens when driving on land).

The BMD-2 is heavier than the BMD-1, but uses the same hull, which means that it has a considerably worse buoyancy reserve.

STRATEGIC MOBILITY

The BMD-2 is rather famous for being an air-droppable "tank", and rightly so. It can be air-dropped directly into the battlefield by appropriate cargo planes such as the Il-76, from an altitude ranging from 2000m to just 500m. It is worth noting that if the transport plane is not flying at low altitudes, it will most certainly be detected and tracked by enemy radars, and so will the parachuting BMD. Although an air insertion is very quick, it is not clandestine.

Besides air drops into enemy territory, the light weight of the BMD-2 makes it very easy to transport in large quantities by plane.

Using the PRSM-925 retro rocket parachute system, the vehicle may be dropped with the entire crew plus passengers from an altitude of 500m to 1500m. The PRSM-925 rocket system needs only one large main parachute. It's primary purpose is to align the retro rocket and the suspended vehicle perfectly perpendicular to the ground, and its secondary purpose is to control the speed of descent, which is still very high. Because there's only one parachute, there is not much clutter that can entangle the vehicle on landing, and because the speed of descent is relatively high up until the retro rockets activate, the amount of time the BMD-2 is visible in the air is significantly reduced. Before being loaded onto a plane, the BMD-2 must loaded onto a shock absorbing pallet beforehand. This is to prevent the vehicle from sinking if it lands in marshy soil.

The rockets are activated by a contact probe deployed from underneath the pallet. They ensure that the rocket activates at the optimum altitude for the softest possible landing.

Alternatively, the RKMS-165 multi-parachute system may be employed:

It involves the use of a bouquet of 9 large primary parachutes, and instead of a rocket booster to soften the landing, a simple air cushion is used instead. Landing through this method is rougher, and is less suitable for a crewed landing. Additionally, the crew needs to remove several straps securing the hull to the air cushion before the vehicle can be put into action. This is far too time consuming for combat insertions, so this method is only used for delivering the BMD-2 to remote areas quickly where an airstrip or a suitable landing zone is not present, but immediate combat is not expected. Air transport is faster than rail transport, and much faster than having the vehicle driven by itself. Air dropped vehicles like the BMD-2 are often the only force multiplier that soldiers may have until heavier equipment can arrive, and that may take days.

Another option lies in the use of heavy transport helicopters. The BMD-2 may be carried the Mi-26 or Mi-10 in particular.

|

| Two BMD-2s about to be loaded into an Mi-26 |

The BMD-2 may also be flown by a Mi-6, but only in an underslung configuration. Two BMD-2s may be transported internally per sortie in an Mi-26, or one in an underslung configuration. The Mi-10 may transport one BMD-2 attached to the fuselage.

References

http://mreadz.com/new/index.php?id=132817&pages=10

NII Stali Fact Sheet on Aluminium Armour

http://www.dishmodels.ru/wshow.htm?mode=P&vmode=T&p=261&id=4395&tp=w

http://vmk.tplants.com/ru/products/bmd2/

http://lzos.ru/en/index.php?option=com_content&task=view&id=72

http://lzos.ru/en/index.php?option=com_content&task=view&id=71

http://kbptula.ru/en/productions/small-arms-guns-grenade-launchers/guns-machine-guns/2a42

http://kubinkamuseum.ru/index.php?option=com_content&view=article&id=76&Itemid=274

https://books.google.com.my/books?id=BNvfNYW6yisC&pg=PA24&lpg=PA24&dq=bmp+squad+leader&source=bl&ots=epAOthRskO&sig=HcU2bjIyxVHBPzUhSHydf0fmiWE&hl=en&sa=X&redir_esc=y#v=onepage&q=bmp%20squad%20leader&f=false

http://www.wk2ammo.com/showthread.php?3203-20x139-shells-for-the-HS-820-(Oerlikon-KAD)-amp-Rh-202-gun

http://www.rheinmetall-defence.com/en/media/editor_media/rm_defence/publicrelations/pressemitteilungen/2013_1/2013_Rheinmetall_IDEX_Medium_Calibre_Ammunition.pdf

http://coollib.com/b/237493/read

Soviet Bloc Elite Forces By Steven J. Zaloga (unreliable)

NII Stali Fact Sheet on Aluminium Armour

http://www.dishmodels.ru/wshow.htm?mode=P&vmode=T&p=261&id=4395&tp=w

http://vmk.tplants.com/ru/products/bmd2/

http://lzos.ru/en/index.php?option=com_content&task=view&id=72

http://lzos.ru/en/index.php?option=com_content&task=view&id=71

http://kbptula.ru/en/productions/small-arms-guns-grenade-launchers/guns-machine-guns/2a42

http://kubinkamuseum.ru/index.php?option=com_content&view=article&id=76&Itemid=274

https://books.google.com.my/books?id=BNvfNYW6yisC&pg=PA24&lpg=PA24&dq=bmp+squad+leader&source=bl&ots=epAOthRskO&sig=HcU2bjIyxVHBPzUhSHydf0fmiWE&hl=en&sa=X&redir_esc=y#v=onepage&q=bmp%20squad%20leader&f=false

http://www.wk2ammo.com/showthread.php?3203-20x139-shells-for-the-HS-820-(Oerlikon-KAD)-amp-Rh-202-gun

http://www.rheinmetall-defence.com/en/media/editor_media/rm_defence/publicrelations/pressemitteilungen/2013_1/2013_Rheinmetall_IDEX_Medium_Calibre_Ammunition.pdf

http://coollib.com/b/237493/read

Bibliography

Soviet Bloc Elite Forces By Steven J. Zaloga (unreliable)