The T-72 is known as one of the most numerous tanks in the world today, and the tank is likely to remain in some form of service for the rest of the 21st Century, so before we examine the history of the T-72, let us see how many of these tanks were actually built. A few years ago, Uralvagonzavod (UVZ) made efforts to declassify much of the history of the T-72 tank, including the number of tanks built by the factory. The table below comes from the factory archives of UVZ, published in the book "T-72/T-90: The Experience of Creating Domestic Main Battle Tanks" authored by S. Ustmantsev and D. Komalkov (head designer of the UVZ transport engineering bureau).

From 1973 to 1990, a total of 18,373 T-72 tanks and T-72 derivatives were manufactured at the UVZ factory floor and another 1,600 tanks were manufactured from 1991 to 1996. The Chelyabinsk Tractor Factory also took part in the manufacture of the T-72 tank, producing 1,894 units themselves between 1978 and 1990. In total, 20,267 T-72 tanks were produced in Soviet Russia, making it the second most numerous tank ever produced in both the USSR and the world, outstripping the T-62 for that title by a slim margin. Of that total, 5,264 T-72A tanks were delivered to the Soviet Army. But how did it come about? The 2010 book "T-72 Ural armor versus NATO" by noted military historian Mikhail Baryatinsky details the history of the development of the tank, and is the source for many of the diagrams and pictures shared below.

Firstly, it should be clear that the T-72 is indeed a "mobilization model" of a sort with slightly inferior performance compared to the later models of the T-64 series. The main factor that relegates the T-72 to this category during its service career in the Soviet Army was its role as the primary tank model for motorized infantry units and other mainline Army units whereas the T-64 and T-80 series tended to be supplied to Guards units. The T-72 was also widely exported during the Cold War, and as such, the T-72 could be rightfully considered the backbone of the Soviet Army and that of many other nations together with the T-55 and the T-62. With that said, some Internet sleuths found this chart of procurement prices showing that the T-72A (1979) was significantly more expensive than the T-64A. The more expensive pricing of the T-72 does not change the fact that it was a less sophisticated product compared to the later models of the T-64 such as the T-64B, although it was not originally intended to be such by the chief designer of the UKBTM design bureau, Leonid Kartsev. In fact, the original T-72 outpaced the T-64A in some technical areas due to the implementation of certain technologies.

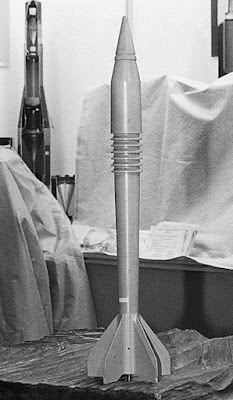

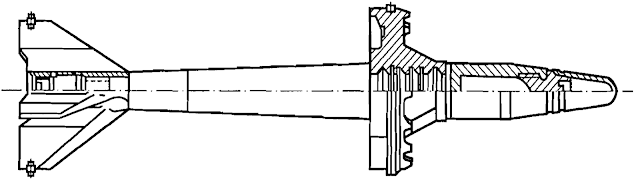

Let us take a look at the Object 167M. It is a precursor to the T-72, but is better described as a T-62 taken to the extreme.

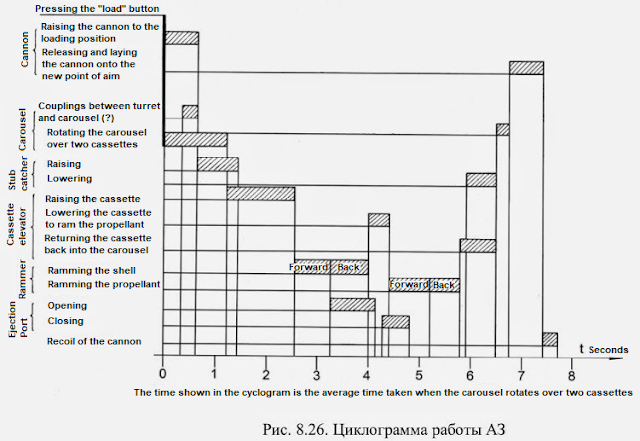

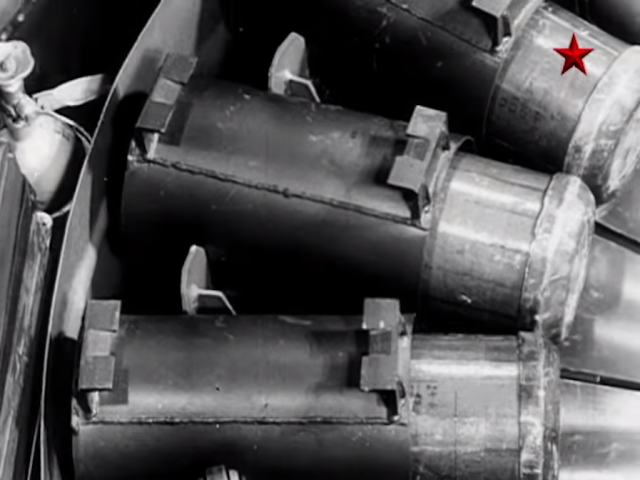

The Object 167M featured the now-famous AZ autoloader, composite armour for the upper glacis and turret, a 125mm D-81T cannon, a V-26 engine which developed 700 HP, a reinforced transmission to deal with the increased power, hydraulically powered gear shifting systems, the new "Liveni" two-plane stabilizer system, and a new suspension composed of six roadwheels with three return rollers. The tank did not enter mass production because the Object 432 had already been ordered to enter production as the T-64 by a resolution from the Council of Ministers of the USSR and the Object 167M had numerous drawbacks of its own. In February 26, 1964, the scientific-technical council GKOT examined the Object 167M project and rejected it. This was the end of the road for the Object 167M, but it was destined to leave its mark on Soviet tank history, as we shall see later on.

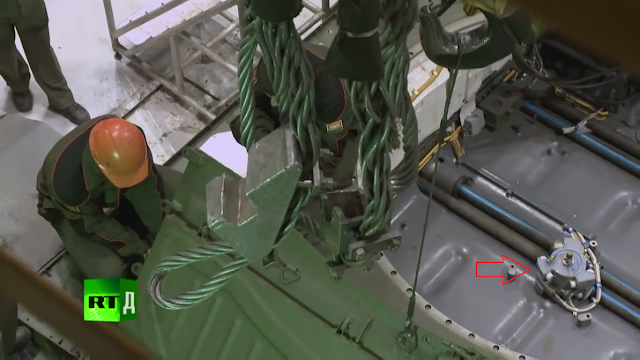

The Minister of Defence Industry S.A Zverev came to the experimental workshop of the Uralvagonzavod factory on October 26, 1967, the 50th anniversary of the October Revolution. After an invitation to enter and examine a modified T-62 with a 125mm gun (a special development in response to Kharkov's failure to begin mass production of the T-64 on schedule) by UKBTM design bureau chief Leonid Kartsev, the minister requested a demonstration. The designer E.E Krivosheya and researcher L.F Terlikov who were loitering around the tank quickly joined the two inside, started it up and activated the autoloader. The minister was impressed by the autoloader and was enthusiastic on the idea of putting it in the T-64, but rejected Kartsev's proposal to also replace the 5TDF engine on the T-64A with a supercharged derivative of the V-2 engine (from the T-34) developed in Chelyabinsk. He only agreed on changing the engine on the next day after a private meeting with the head of the Military Industrial Commission I.V Okunev. It was agreed that six T-64A tanks were to be sent to UVZ to be given the modifications specified by Kartsev, but the minister also dictated that the suspension and chassis were to be untouched. On 5 January, 1968, Zverev officially gave the order to begin the "modernization" of the T-64A by the Uralvagonzavod factory. Thus the life of the T-72 began, but for the next few years, all prototypes of Kartsev's new tanks would either be modifications of these six T-64A tanks or modified copies thereof.

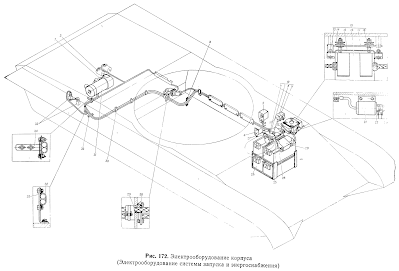

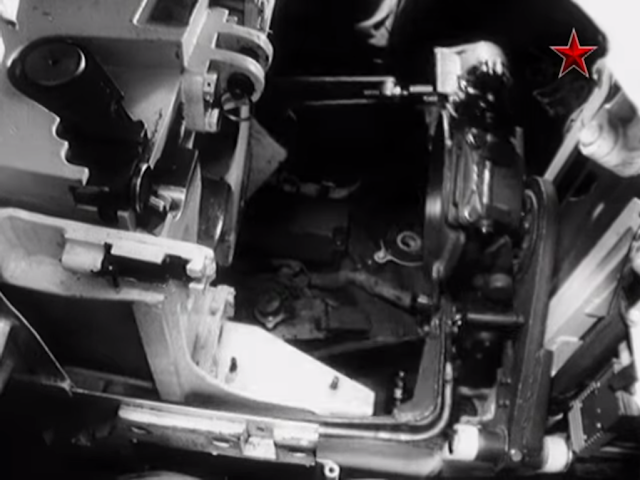

The first of these modifications, dubbed "Object 172", was completed in the summer of 1968, and the second was completed in September of that same year. The Object 172 differed from the T-64A obr. 196 in the fighting compartment which had to be rearranged to fit the new autoloader, and in the engine compartment which was completely reworked for the V-45K engine and T-54-style cooling system.

Because the modifications were focused only on internal components and the engine compartment, the Object 172 was practically indistinguishable from a typical T-64A obr. 1989 from the front, but from the rear, the turret was clearly modified for the autoloader's ramming and ejection system, while the engine deck was completely distinct from that of the T-64 series. The engine compartment itself was also lengthened to accommodate the new powertrain and cooling system, so the tank is not as compact as the T-64 in length. The left side of the hull gained an exhaust port just above the second rearmost roadwheel - a location reminiscent of the earlier T-54 and T-62.

Baryatinsky's book gives us the details of the late stages of gestation of the T-72. Here are a few translated paragraphs:

"... in the Design Bureau of the UVZ, which since August 1969 was headed by V.N. Venediktov, it was decided to use the chassis of the Object 167 with rubberized roadwheels of increased diameter and more durable tracks with open metal track pins [author's note: OMSh] similar to those of the T-62 tank. The development of this tank was carried out under the designation "Object 172M". The engine, boosted to 780 hp, received the index of V-46. A two-stage air-cleaning cassette system was introduced, similar to that used on the T-62 tank. The weight of the Object 172M increased to 41 tons, but the mobility characteristics remained at the same level due to the increase in engine power by 80 hp, the capacity of fuel tanks by 100 liters and the width of the track by 40 mm.

From November 1970 to April 1971, Object 172M passed a full cycle of factory tests and then on the 6th of May 1971, it was presented to the Minister of Defence A.A. Grechko and to the Minister of Defence Industry SA. Zverev. By the beginning of the summer, a test lot was created from 15 vehicles, which, together with the T-64A and T-80 tanks, passed many months of testing of an unprecedented scale. At the suggestion of Major-General Yuri M. Potapov, a battalion composed of three companies with tank platoons was formed. Each company was formed from tanks of the same type. The route of the traffic was chosen from Dnepropetrovsk through Ukraine to Belorussia to Slutsk and then back to Dnepropetrovsk, and then through the Donbass and the North Caucasus to Baku, across the sea by ferry to Krasnovodsk, through the Karakum desert and the Kopetdag mountain range. The tests were due to be completed at a range, 60 km from Ashgabat. During the march, live firing tests were conducted at various firing ranges, and platoon and company level exercises with live firing and maneuvering were carried out at various tankodroms [author's note: training grounds].

After the end of the tests, a report with the title "Report on the results of military trials of 15 tanks 172M, manufactured by Uralvagonzavod in 1972" was submitted. The final part of the report contained these remarks:

In accordance with the decision of the Central Committee of the CPSU and the Council of Ministers of the USSR of August 7, 1973, Object 172M was adopted by the Soviet Army under the name of T-72 "Ural". The official order of the Minister of Defense of the USSR was published on August 13, 1973. In the same year, a pilot batch of 30 tanks was produced at Uralvagonzavod."

And thus, the T-72 was born. An amalgamation of the T-64A and the Object 167M, the T-72 would go on to become the second most widely produced tank in the world, behind only the T-54.

In the end, the T-72 was similar enough to the T-64 that it was not easy to tell them apart at first glance, yet different enough that there was virtually no commonality in parts between the two tank families. This was one of the many headaches caused by the rivalries in the Soviet tank building industry, but still, this did not change the fact that the T-72 was an extremely capable tank. When viewed in terms of cost efficiency, the T-72 was second to none during its heyday and still remains a relatively competitive product to this day if given sufficient upgrades.

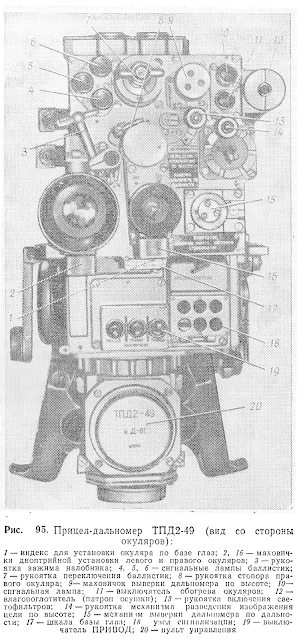

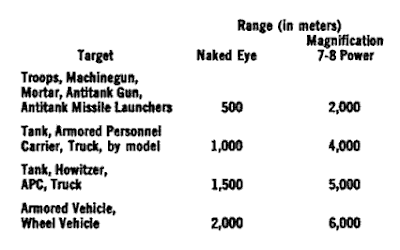

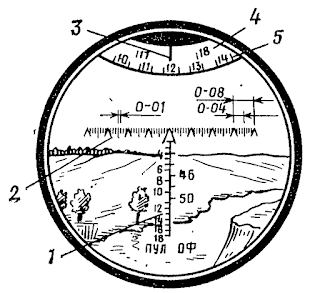

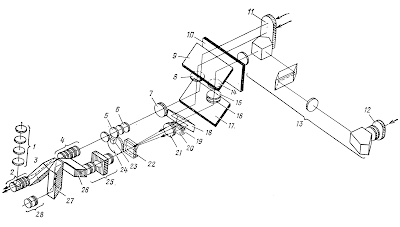

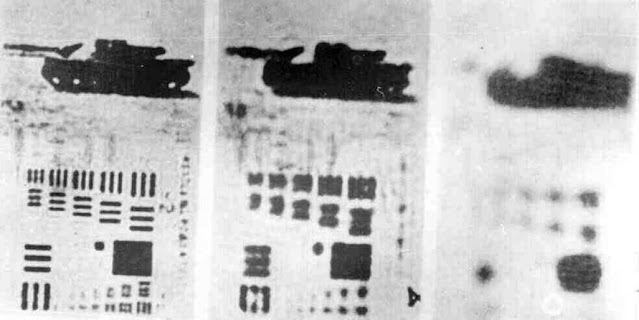

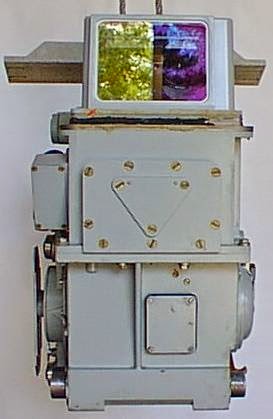

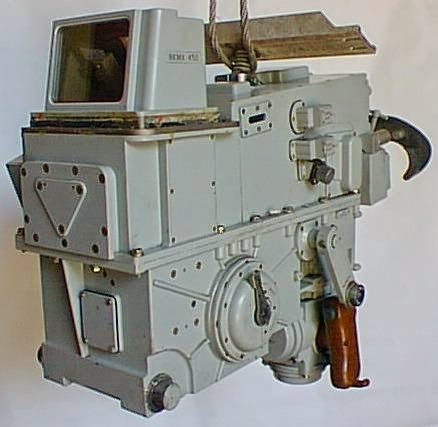

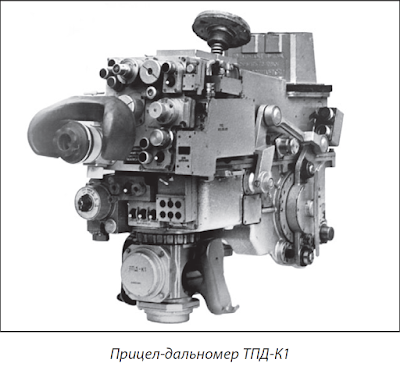

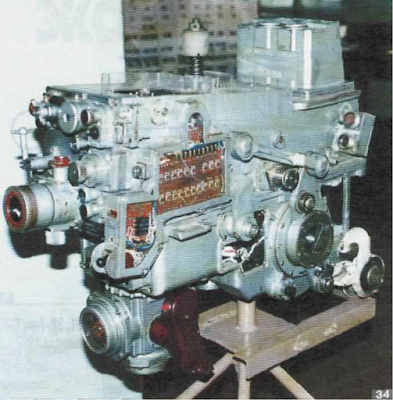

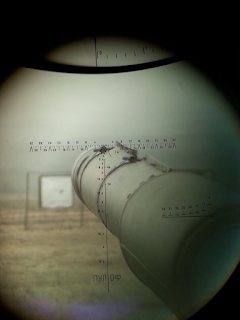

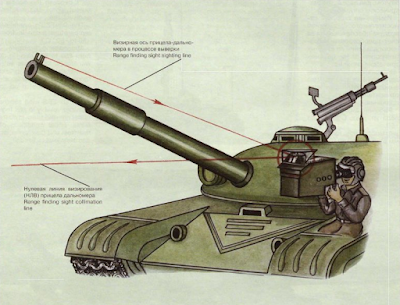

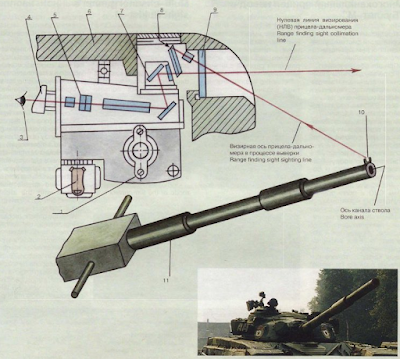

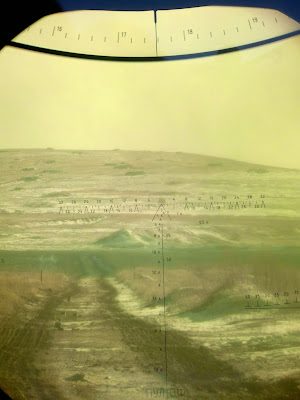

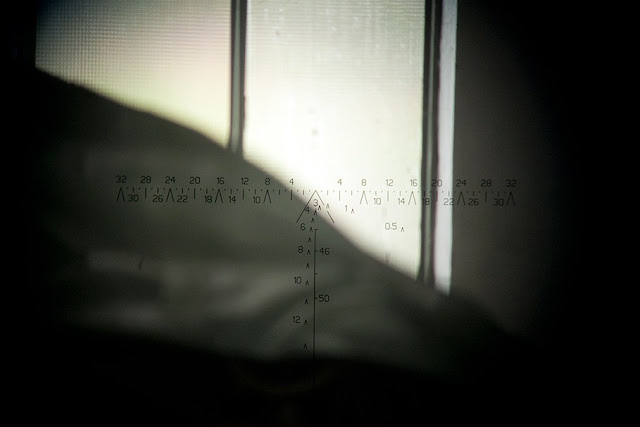

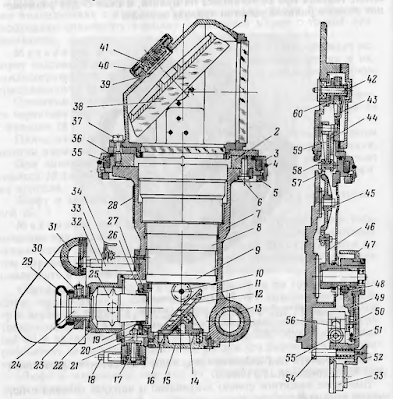

Although many T-72 models could be considered technically inferior to a T-64 or T-80 counterpart from the same period, the difference in combat capabilities was generally quite small. According to captured Soviet documentation from 1977 presented in this CIA report, the combat potential coefficient of the T-64A is 1.50 and the T-72 is rated at 1.50. Thus, the T-72 was considered to be the equal of the T-64A during the earlier years of its life. However, the gap in capabilities appears to widen as the years go by: the combat potential of the T-64B is rated at 2.10 and the "T-72 with TPD-K1" is rated at only 1.70. However, the T-72A (1979) did not yet exist by the time the document was published (1977) whereas the T-64B (1976) was already in mass production, so it is not so easy to directly compare the T-64B with the closest T-72 counterpart. Generally speaking, however, the determining factor appears to be in the fire control system. Indeed, the inclusion of the TPD-K1 laser rangefinding sight alone apparently gave the T-72 a 0.2 point advantage over the basic model. The additional advantages enjoyed by the T-64B included the ability to fire guided missiles which the T-72 family lacked until 1985 when the T-72B began mass production. The T-72 series also retained the same TPD-K1 sight in one form or another throughout its career in the 80's and into modern times. On the other hand, the T-64A began with the TPD-2-49 sight in 1972 which the T-72 Ural shared, but the T-64 was upgraded to the T-64B variant and was equipped with the substantially more advanced 1A33 sighting complex with the 1G42 sight in 1976 and retained it until 1987 when the T-64 family was discontinued altogether. However, the cost efficiency of the T-72 was a different matter.

In the book "Combat Vehicles of Uralvagonzavod: T-72 Tank" published by the Information and PR department of Uralvagonzavod, it is claimed that the money spent on purchasing a single T-80U could otherwise be invested in three T-72Bs (with an additional 16,000 Rubles), so in other words, the funds required to purchase two T-80U tanks could cover the cost of a platoon of T-72B tanks as well as a moderate supply of spares. One may be reminded of the stereotype of the Soviet Army favouring hordes of inferior tanks instead of a numerically small collection of technically superior ones, but this is simply not the case. Having a large number of tanks is necessary to ensure that tank support is regularly available to the infantry and there must be enough tanks to fulfill certain operational and strategic objectives, including having enough reserves to support and consolidate territorial gains.

Referring to the theory of cost efficiency detailed in the book "Tanks: Tactics, Technology, Armament" by Yu.P Kostenko, the Uralvagonzavod editors claim that the calculated cost efficiency coefficient of the T-72B is 3.38 whereas the calculated cost efficiency coefficient of the T-80U is only 1.25. Theoretically, the cost efficiency of the T-72B is 2.7 times higher. The method by which combat effectiveness is quantified is a complex affair so it is difficult to independently verify these numbers using third party (i.e non-UVZ) primary sources, but this is merely academic. The high cost effectiveness of the T-72 undoubtedly had a large influence on the monumental export success of the tank, especially considering that the core customer base for Soviet and Russian arms are Second World or Third World nations that typically do not have a large procurement budget and want the maximum return on their investment.

Furthermore, Kostenko writes in his 2001 monograph "Tank: Man, Environment, Machine" that the time needed for maintenance after 350 km of operation in a T-72B corresponds to 200 km of operation for a T-64B and 100 km of operation for a T-80B. In other words, the amount of maintenance required for a T-72B for any given unit of distance is 3.5 times less than a T-80B and 1.75 times less than a T-64B.

But before we take a look at the T-72 in earnest, we must first remember that the original Ural variant underwent several major upgrades throughout its lifetime, creating significant discrepancies between each successive model. To complicate matters, each model in itself may have subtle improvements implemented during overhauls. For example, the transition from the T-72 Ural to the T-72A was gradual, with many of the changes embodied by the so-called "Ural-1" model that contained a mixture of features from both the T-72 Ural and the T-72A. The T-72 Ural-1 entered service in 1975-1976, depending on the source. Russian historian A.V. Karpenko states that this modification was accepted into service in 1975.

From 1973 to 1990, a total of 18,373 T-72 tanks and T-72 derivatives were manufactured at the UVZ factory floor and another 1,600 tanks were manufactured from 1991 to 1996. The Chelyabinsk Tractor Factory also took part in the manufacture of the T-72 tank, producing 1,894 units themselves between 1978 and 1990. In total, 20,267 T-72 tanks were produced in Soviet Russia, making it the second most numerous tank ever produced in both the USSR and the world, outstripping the T-62 for that title by a slim margin. Of that total, 5,264 T-72A tanks were delivered to the Soviet Army. But how did it come about? The 2010 book "T-72 Ural armor versus NATO" by noted military historian Mikhail Baryatinsky details the history of the development of the tank, and is the source for many of the diagrams and pictures shared below.

Firstly, it should be clear that the T-72 is indeed a "mobilization model" of a sort with slightly inferior performance compared to the later models of the T-64 series. The main factor that relegates the T-72 to this category during its service career in the Soviet Army was its role as the primary tank model for motorized infantry units and other mainline Army units whereas the T-64 and T-80 series tended to be supplied to Guards units. The T-72 was also widely exported during the Cold War, and as such, the T-72 could be rightfully considered the backbone of the Soviet Army and that of many other nations together with the T-55 and the T-62. With that said, some Internet sleuths found this chart of procurement prices showing that the T-72A (1979) was significantly more expensive than the T-64A. The more expensive pricing of the T-72 does not change the fact that it was a less sophisticated product compared to the later models of the T-64 such as the T-64B, although it was not originally intended to be such by the chief designer of the UKBTM design bureau, Leonid Kartsev. In fact, the original T-72 outpaced the T-64A in some technical areas due to the implementation of certain technologies.

Let us take a look at the Object 167M. It is a precursor to the T-72, but is better described as a T-62 taken to the extreme.

The Object 167M featured the now-famous AZ autoloader, composite armour for the upper glacis and turret, a 125mm D-81T cannon, a V-26 engine which developed 700 HP, a reinforced transmission to deal with the increased power, hydraulically powered gear shifting systems, the new "Liveni" two-plane stabilizer system, and a new suspension composed of six roadwheels with three return rollers. The tank did not enter mass production because the Object 432 had already been ordered to enter production as the T-64 by a resolution from the Council of Ministers of the USSR and the Object 167M had numerous drawbacks of its own. In February 26, 1964, the scientific-technical council GKOT examined the Object 167M project and rejected it. This was the end of the road for the Object 167M, but it was destined to leave its mark on Soviet tank history, as we shall see later on.

The Minister of Defence Industry S.A Zverev came to the experimental workshop of the Uralvagonzavod factory on October 26, 1967, the 50th anniversary of the October Revolution. After an invitation to enter and examine a modified T-62 with a 125mm gun (a special development in response to Kharkov's failure to begin mass production of the T-64 on schedule) by UKBTM design bureau chief Leonid Kartsev, the minister requested a demonstration. The designer E.E Krivosheya and researcher L.F Terlikov who were loitering around the tank quickly joined the two inside, started it up and activated the autoloader. The minister was impressed by the autoloader and was enthusiastic on the idea of putting it in the T-64, but rejected Kartsev's proposal to also replace the 5TDF engine on the T-64A with a supercharged derivative of the V-2 engine (from the T-34) developed in Chelyabinsk. He only agreed on changing the engine on the next day after a private meeting with the head of the Military Industrial Commission I.V Okunev. It was agreed that six T-64A tanks were to be sent to UVZ to be given the modifications specified by Kartsev, but the minister also dictated that the suspension and chassis were to be untouched. On 5 January, 1968, Zverev officially gave the order to begin the "modernization" of the T-64A by the Uralvagonzavod factory. Thus the life of the T-72 began, but for the next few years, all prototypes of Kartsev's new tanks would either be modifications of these six T-64A tanks or modified copies thereof.

The first of these modifications, dubbed "Object 172", was completed in the summer of 1968, and the second was completed in September of that same year. The Object 172 differed from the T-64A obr. 196 in the fighting compartment which had to be rearranged to fit the new autoloader, and in the engine compartment which was completely reworked for the V-45K engine and T-54-style cooling system.

Because the modifications were focused only on internal components and the engine compartment, the Object 172 was practically indistinguishable from a typical T-64A obr. 1989 from the front, but from the rear, the turret was clearly modified for the autoloader's ramming and ejection system, while the engine deck was completely distinct from that of the T-64 series. The engine compartment itself was also lengthened to accommodate the new powertrain and cooling system, so the tank is not as compact as the T-64 in length. The left side of the hull gained an exhaust port just above the second rearmost roadwheel - a location reminiscent of the earlier T-54 and T-62.

"... in the Design Bureau of the UVZ, which since August 1969 was headed by V.N. Venediktov, it was decided to use the chassis of the Object 167 with rubberized roadwheels of increased diameter and more durable tracks with open metal track pins [author's note: OMSh] similar to those of the T-62 tank. The development of this tank was carried out under the designation "Object 172M". The engine, boosted to 780 hp, received the index of V-46. A two-stage air-cleaning cassette system was introduced, similar to that used on the T-62 tank. The weight of the Object 172M increased to 41 tons, but the mobility characteristics remained at the same level due to the increase in engine power by 80 hp, the capacity of fuel tanks by 100 liters and the width of the track by 40 mm.

From November 1970 to April 1971, Object 172M passed a full cycle of factory tests and then on the 6th of May 1971, it was presented to the Minister of Defence A.A. Grechko and to the Minister of Defence Industry SA. Zverev. By the beginning of the summer, a test lot was created from 15 vehicles, which, together with the T-64A and T-80 tanks, passed many months of testing of an unprecedented scale. At the suggestion of Major-General Yuri M. Potapov, a battalion composed of three companies with tank platoons was formed. Each company was formed from tanks of the same type. The route of the traffic was chosen from Dnepropetrovsk through Ukraine to Belorussia to Slutsk and then back to Dnepropetrovsk, and then through the Donbass and the North Caucasus to Baku, across the sea by ferry to Krasnovodsk, through the Karakum desert and the Kopetdag mountain range. The tests were due to be completed at a range, 60 km from Ashgabat. During the march, live firing tests were conducted at various firing ranges, and platoon and company level exercises with live firing and maneuvering were carried out at various tankodroms [author's note: training grounds].

After the end of the tests, a report with the title "Report on the results of military trials of 15 tanks 172M, manufactured by Uralvagonzavod in 1972" was submitted. The final part of the report contained these remarks:

- Tanks have passed the tests, but the lifespan of the tracks of 4,500 - 5,000 km is insufficient and does not fulfill the requirement for tank travelling capability of a distance of 6,500 - 7,000 km without replacement of tracks.

- Tank 172M (warranty period - 3,000 km) and engine V-46 (350 m / h (?)) worked reliably. In the course of further testing up to 10,000 - 11,000 km, most of the units and assemblies, including the V-46 engine, operated reliably, but a number of major units and assemblies showed insufficient lifespan and reliability.

- The tank is recommended for adoption into the armed services and serial production, provided that the identified shortcomings are eliminated and the effectiveness of their elimination is checked before serial production. The scope and time frames for improvements and inspections should be agreed between the Ministry of Defense and the Ministry of Defense Industry.

In accordance with the decision of the Central Committee of the CPSU and the Council of Ministers of the USSR of August 7, 1973, Object 172M was adopted by the Soviet Army under the name of T-72 "Ural". The official order of the Minister of Defense of the USSR was published on August 13, 1973. In the same year, a pilot batch of 30 tanks was produced at Uralvagonzavod."

And thus, the T-72 was born. An amalgamation of the T-64A and the Object 167M, the T-72 would go on to become the second most widely produced tank in the world, behind only the T-54.

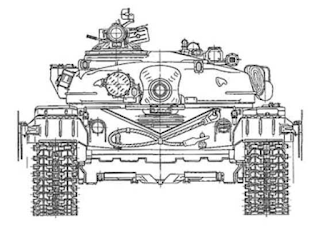

In the end, the T-72 was similar enough to the T-64 that it was not easy to tell them apart at first glance, yet different enough that there was virtually no commonality in parts between the two tank families. This was one of the many headaches caused by the rivalries in the Soviet tank building industry, but still, this did not change the fact that the T-72 was an extremely capable tank. When viewed in terms of cost efficiency, the T-72 was second to none during its heyday and still remains a relatively competitive product to this day if given sufficient upgrades.

Although many T-72 models could be considered technically inferior to a T-64 or T-80 counterpart from the same period, the difference in combat capabilities was generally quite small. According to captured Soviet documentation from 1977 presented in this CIA report, the combat potential coefficient of the T-64A is 1.50 and the T-72 is rated at 1.50. Thus, the T-72 was considered to be the equal of the T-64A during the earlier years of its life. However, the gap in capabilities appears to widen as the years go by: the combat potential of the T-64B is rated at 2.10 and the "T-72 with TPD-K1" is rated at only 1.70. However, the T-72A (1979) did not yet exist by the time the document was published (1977) whereas the T-64B (1976) was already in mass production, so it is not so easy to directly compare the T-64B with the closest T-72 counterpart. Generally speaking, however, the determining factor appears to be in the fire control system. Indeed, the inclusion of the TPD-K1 laser rangefinding sight alone apparently gave the T-72 a 0.2 point advantage over the basic model. The additional advantages enjoyed by the T-64B included the ability to fire guided missiles which the T-72 family lacked until 1985 when the T-72B began mass production. The T-72 series also retained the same TPD-K1 sight in one form or another throughout its career in the 80's and into modern times. On the other hand, the T-64A began with the TPD-2-49 sight in 1972 which the T-72 Ural shared, but the T-64 was upgraded to the T-64B variant and was equipped with the substantially more advanced 1A33 sighting complex with the 1G42 sight in 1976 and retained it until 1987 when the T-64 family was discontinued altogether. However, the cost efficiency of the T-72 was a different matter.

In the book "Combat Vehicles of Uralvagonzavod: T-72 Tank" published by the Information and PR department of Uralvagonzavod, it is claimed that the money spent on purchasing a single T-80U could otherwise be invested in three T-72Bs (with an additional 16,000 Rubles), so in other words, the funds required to purchase two T-80U tanks could cover the cost of a platoon of T-72B tanks as well as a moderate supply of spares. One may be reminded of the stereotype of the Soviet Army favouring hordes of inferior tanks instead of a numerically small collection of technically superior ones, but this is simply not the case. Having a large number of tanks is necessary to ensure that tank support is regularly available to the infantry and there must be enough tanks to fulfill certain operational and strategic objectives, including having enough reserves to support and consolidate territorial gains.

Referring to the theory of cost efficiency detailed in the book "Tanks: Tactics, Technology, Armament" by Yu.P Kostenko, the Uralvagonzavod editors claim that the calculated cost efficiency coefficient of the T-72B is 3.38 whereas the calculated cost efficiency coefficient of the T-80U is only 1.25. Theoretically, the cost efficiency of the T-72B is 2.7 times higher. The method by which combat effectiveness is quantified is a complex affair so it is difficult to independently verify these numbers using third party (i.e non-UVZ) primary sources, but this is merely academic. The high cost effectiveness of the T-72 undoubtedly had a large influence on the monumental export success of the tank, especially considering that the core customer base for Soviet and Russian arms are Second World or Third World nations that typically do not have a large procurement budget and want the maximum return on their investment.

Furthermore, Kostenko writes in his 2001 monograph "Tank: Man, Environment, Machine" that the time needed for maintenance after 350 km of operation in a T-72B corresponds to 200 km of operation for a T-64B and 100 km of operation for a T-80B. In other words, the amount of maintenance required for a T-72B for any given unit of distance is 3.5 times less than a T-80B and 1.75 times less than a T-64B.

But before we take a look at the T-72 in earnest, we must first remember that the original Ural variant underwent several major upgrades throughout its lifetime, creating significant discrepancies between each successive model. To complicate matters, each model in itself may have subtle improvements implemented during overhauls. For example, the transition from the T-72 Ural to the T-72A was gradual, with many of the changes embodied by the so-called "Ural-1" model that contained a mixture of features from both the T-72 Ural and the T-72A. The T-72 Ural-1 entered service in 1975-1976, depending on the source. Russian historian A.V. Karpenko states that this modification was accepted into service in 1975.

In essence, the T-72 Ural-1 was effectively the first serial model of T-72 tank to implement the features tested from 1970-75 on the Object 175 and from 1972-1974 on the Object 172-2M "Буйвол" (Buffalo) experimental series, with a significant degree of overlap between the two models. This manifested itself quite tangibly, as when viewing a parts catalogue for a T-72, it can be seen that a large proportion of the parts do not bear a 172 product code, but rather a 175 product code.

The vast majority of the Soviet Army's T-72 tanks up until 1979 was a T-72 Ural-1 model of some type, and this is instantly obvious when we examine the production record of the T-72: the production volume at Nizhny Tagil in 1975 and 1976 alone was 700 units and 1,017 units respectively, whereas only 250 units were released during the entire production run of the original T-72 Ural model from 1973 to 1974.

Since 1977, the T-72 Ural-1 already began to be produced with a new turret with a "Kvartz" non-metallic filler. This turret was standard for the T-72A (Object 172M-1) and became associated with it. As such, there were at least two types of T-72 Ural-1 tanks with major differences. The transition of the T-72A to the T-72B was similarly difficult to track. The T-72B was created out of the "Improved T-72A" project, and such tanks entered service as T-72A tanks years before the T-72B itself was officially adopted. According to Alexey Khlopotov, the 172.10.077SB turret commonly associated with the T-72B entered production in September 1982 and the T-72A began to receive these turrets in 1983 together with a new hull and a new upper glacis armour design. Other improvements such as the V-84 engine would be installed as late as 1984, further blurring the line between the latest T-72A models and the T-72B1. These late model T-72A tanks have the external appearance of a T-72B, but are not actual T-72B tanks (Object 184). Without going into very much detail, we can condense the evolution of the T-72 tank into a few main models.

Object 172M (T-72 Ural) 1973-1974

The original T-72 model with a monolithic cast steel turret and optical coincidence rangefinder-based sighting system. The IR spotlight was originally located on the left side of the cannon like the T-64A, but it was relocated to the right side in 1974 in order to improve driver safety.

Object 172M1 (T-72 Ural-1) 1975-1979

In this model, the "Gill" armour panels on the side of the hull from the T-72 Ural (originally from the T-64) were replaced with conventional side skirts sometime in the later half of its production run. The optical coincidence rangefinder-based sighting system was replaced by a laser rangefinder-based version sometime during the production run, at an unknown point. Modified turrets lacking the protrusion for the second optic port for the coincidence rangefinder were devised for these variants. The tank also began to receive a thermal shroud on the gun barrel in 1975.

Object 172M-1 (T-72A) 1979-1983

In 1976, the UKBTM design bureau was instructed by the Ministry of Defence to carry out a comprehensive modernization of the T-72 in order to increase its combat and operational characteristics. This work concluded with the adoption of the T-72A into the Soviet Army in 1979. Almost everything was changed; the tank had a revised hull armour and a new turret with a composite filler was implemented, the D-81TM cannon was installed, the 902A "Tucha" smoke grenade system was added, a new convoy light with a numerical display was installed, and more.

Object 184 (T-72B) 1985

Second serious upgrade of the T-72. The new tank featured completely revised hull and turret armour, a new autoloader, a guided missile firing capability, a new cannon, a new engine, new sighting systems, and more.

Object 184-1 (T-72B1) 1985

Simplified T-72B variant without the missile firing capability and with the original Ural autoloader. This aspect of the T-72B1 is examined later on in the article, in the section on the autoloader.

The T-72B itself was subject to a modernization project, initiated by the decree No. 741-208 of the USSR Council of Ministers on the 19th of June 1986. The "Improved T-72B" project, under the Object 188 index, entered service in 1992 as the T-90.

Again, it must be stressed that this is only a very basic list of variants. It is unwise to generalize with regards to the T-72, as the model designation sometimes does not reveal the full story.

In terms of ergonomic design, the T-72 is similar to the T-64, greatly superior to the T-62 and T-55, and broadly on par with many contemporary tanks. This is despite the extremely low height of the tank even compared to the T-62 and T-55, and the simple reason is that the use of an autoloader eliminated the need to allocate enough vertical space for a human loader to stand inside the tank.

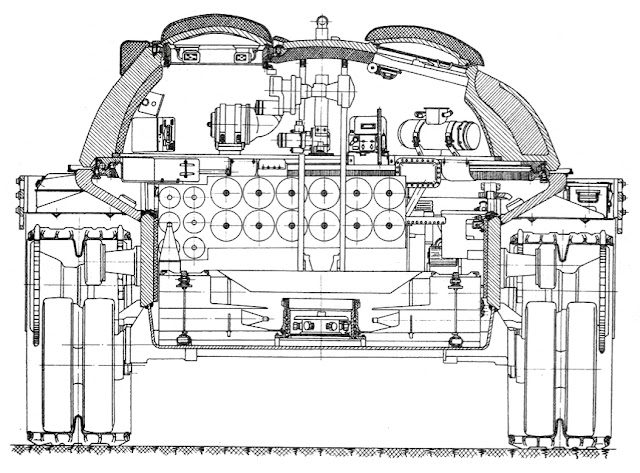

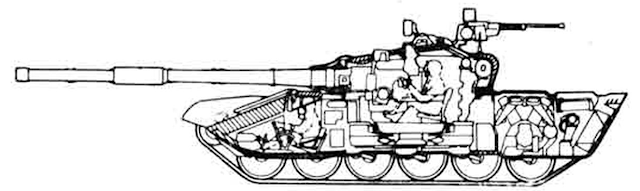

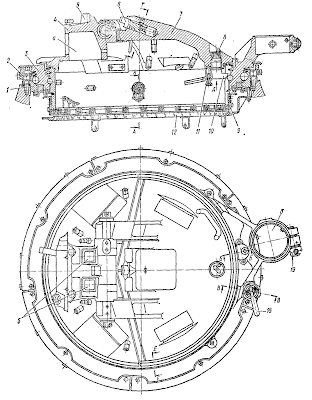

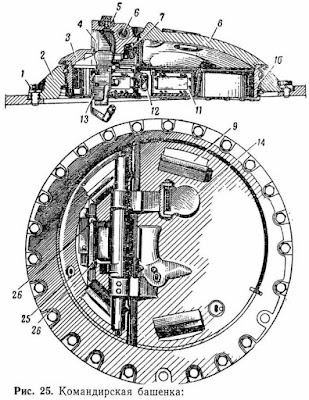

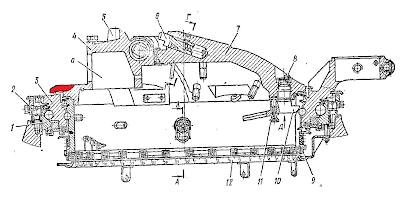

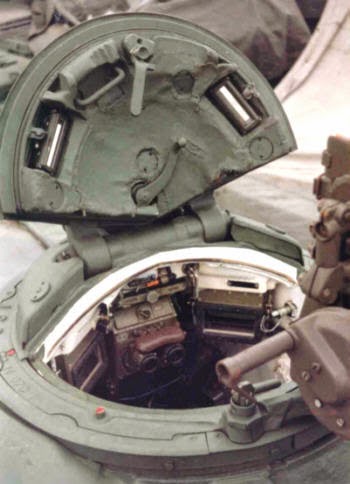

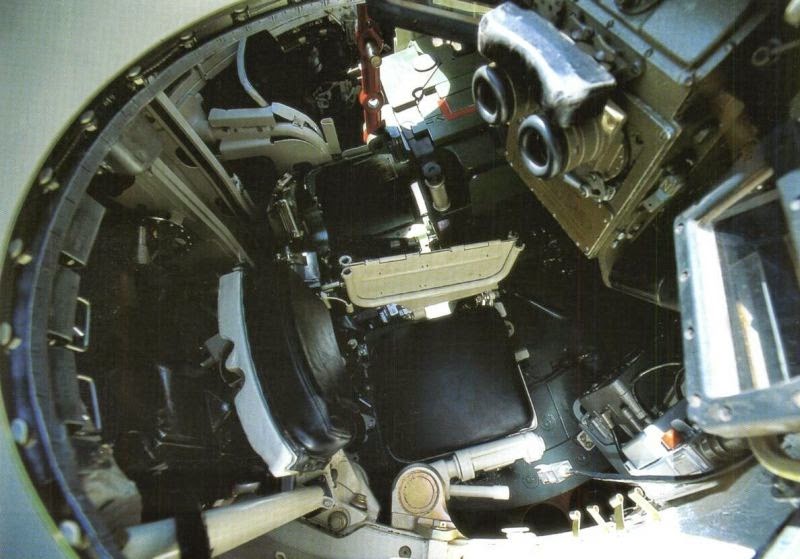

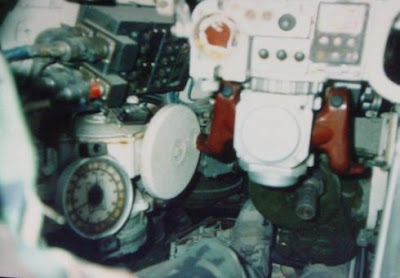

The reduction to a three-man crew also enabled a more spacious turret crew layout to be implemented where the gunner and commander occupied their own halves of the turret, and the amount of space for the driver also increased. If we refer to this diagram from "Human Factors and Scientific Progress in Tank Building" by M.N. Tikhonov and I.D. Kudrin courtesy of Peter Samsonov, it is seen that the commander of a T-72 has 0.615 cubic meters of space, the gunner has 0.495 cubic meters of space and the driver has 0.864 cubic meters of space. However, the commander of a T-72 apparently has much less space compared to a T-55 commander (0.828 cubic meters), but this is obviously not possible. For one, the commander in a T-55 has to wrap his legs around the gunner seated in front of him because there is simply not enough legroom and the breech guard squeezes him against the turret wall where the radio is located. It is the exact opposite for the T-72. As the commander's station in the T-72 is completely separated from the gunner's station, there is nothing in front of him below chest level, and as a result, he has an abundance of legroom and sufficient headroom is guaranteed. It is perfectly possible for exceptionally tall people to command a T-72 without any ergonomic issues, and the commander can stretch his legs out as far as he desires even when the turret rotates. The difference of 0.1 cubic meters between the T-72 and the T-64A is also highly suspect, given that the two tanks are so similar.

According to the article "Elements of Tank Design" by Gerald A. Halbert published in the November-December 1983 issue of ARMOR magazine, a seated man needs 0.4 cubic meters of space while wearing an NBC suit, a loader needs 0.8 cubic meters of space, and a driver needs 0.6 cubic meters of space. Halbert states that an additional 10% of space is needed for habitability and essential movement, so in actuality, a seated man wearing an NBC suit requires 0.44 cubic meters, a loader needs 0.88 cubic meters, and a driver needs 0.66 cubic meters. From this, it can be seen that the internal space provided for the T-72 commander greatly exceeds the ergonomic requirements for a seated man and the space provided for the gunner is still comfortably in excess of the requirements. The space provided for the driver of the T-72 also greatly exceeds the requirements. Furthermore, the rational and efficient layout of the controls and equipment in the tank facilitate crew comfort and ease of operation to a degree that cannot be expressed plainly in terms of volume.

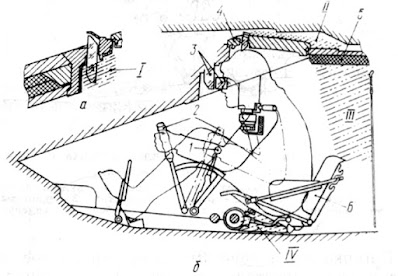

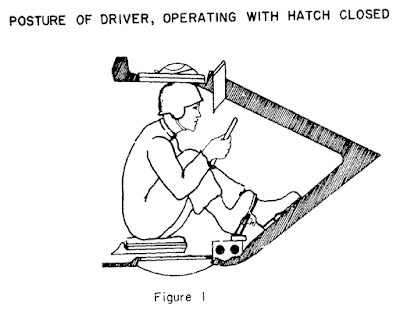

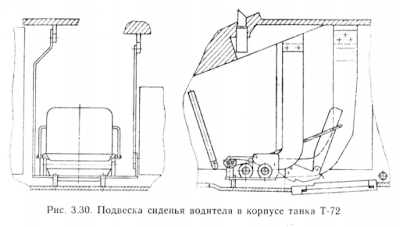

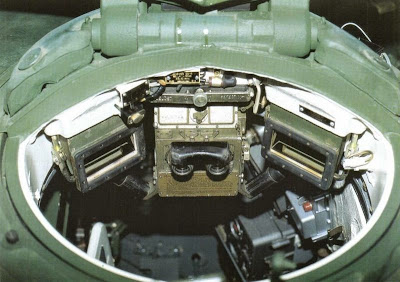

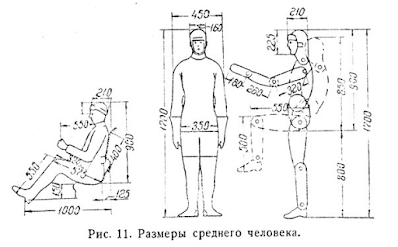

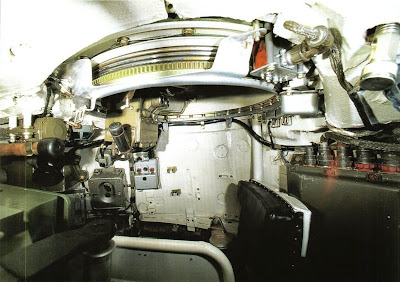

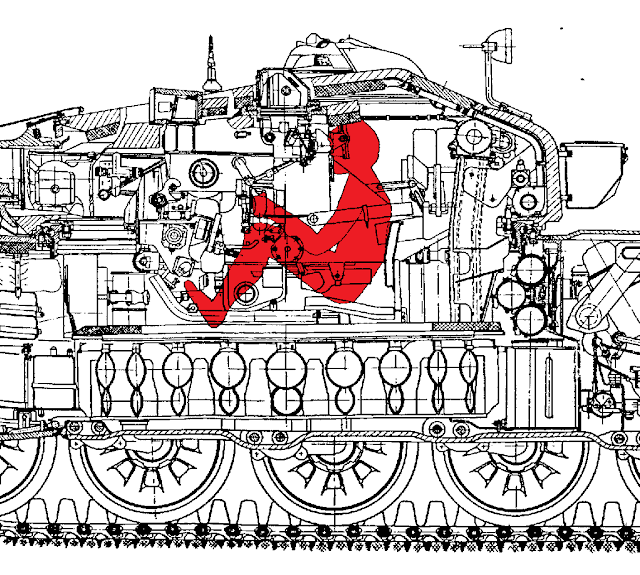

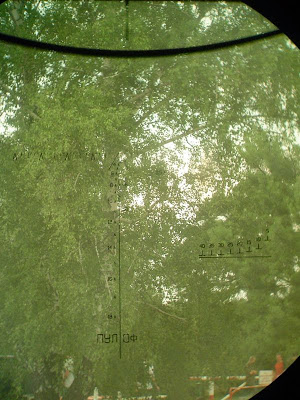

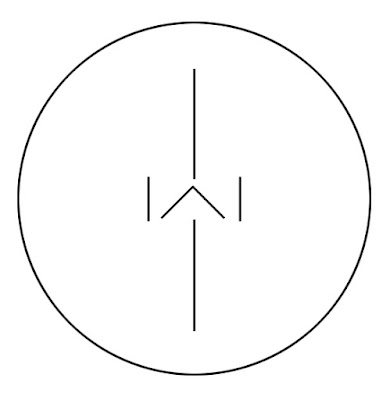

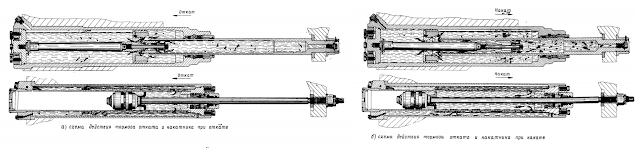

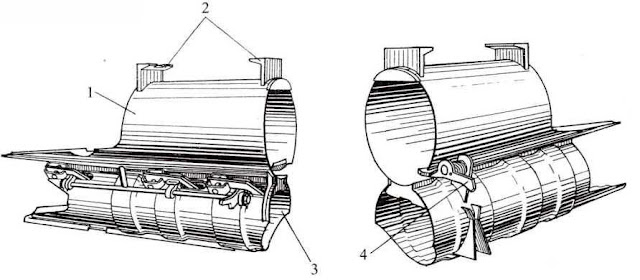

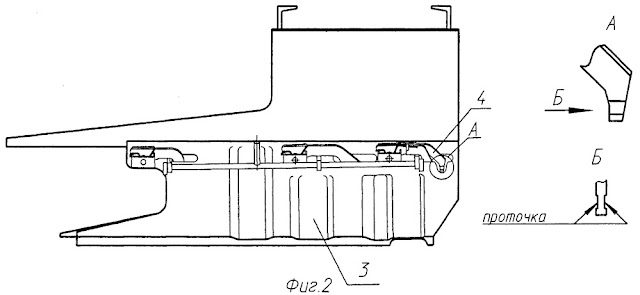

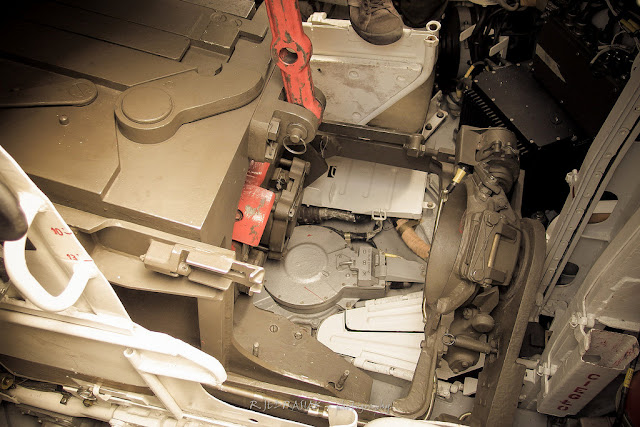

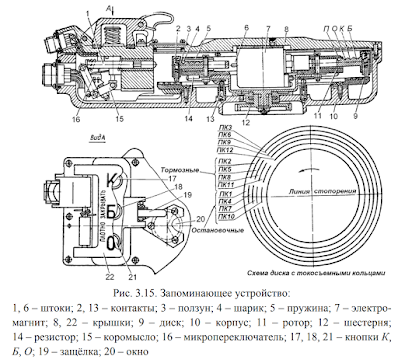

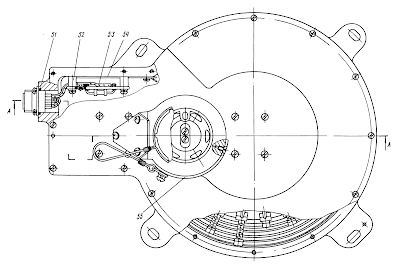

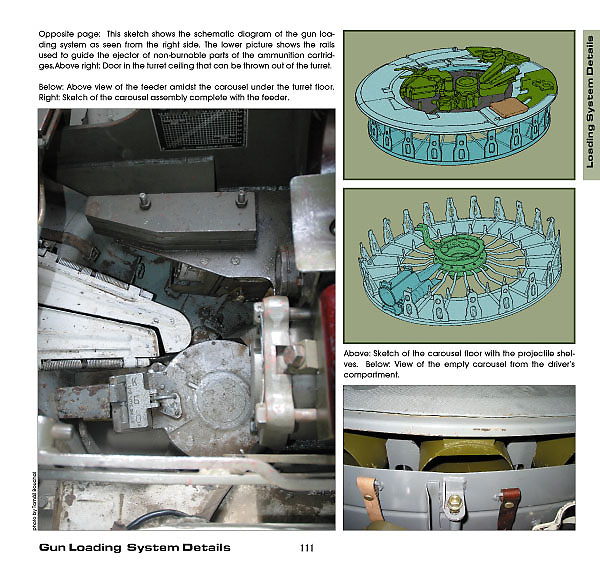

According to Sergey Suvorov, the use of an carousel-type autoloader in the T-72 as opposed to a basket-type autoloader as in the T-64 reduced the vertical space in the tank by around 25 cm. However, the height of the crew compartment in the turret was still more than sufficient, as the crew members are seated at all times when performing their duties. In the T-72, the seats for both the commander and gunner are only a short distance above the tallest point of the false floor of the turret so both crew members sit with their legs outstretched. The gunner's seat is fixed at a height of 150mm above the false floor, and the commander's seat has a variable height. This matched the minimum seat height figure of 150mm used as a reference in Soviet tank ergonomics design textbooks. Referring to the drawing below, it can be seen that the seated height of an average man wearing a tankers' uniform with a standard Soviet tankers' helmet is 1,050mm including a seat with a height of 150mm. The height of the hull and turret of the tank is 1,730mm (excluding ground clearance), and the maximum height of the AZ autoloader carousel is 450mm. Therefore, the internal height in the fighting compartment of the turret after subtracting the thickness of the turret roof and anti-radiation lining is up to 1,200mm. The commander's cupola extends above the turret roof, so in actuality, the vertical space allocated to the commander significantly exceeds this figure, but on the other hand, the turret roof over the gunner's station is sloped which reduces the gunner's headroom by a few inches. From this, it is clear that even a man of extremely tall stature would be able to fit in the commander's station and the gunner's station would still easily accommodate a man of average height.

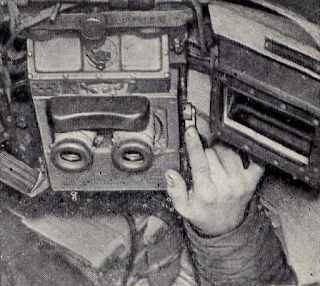

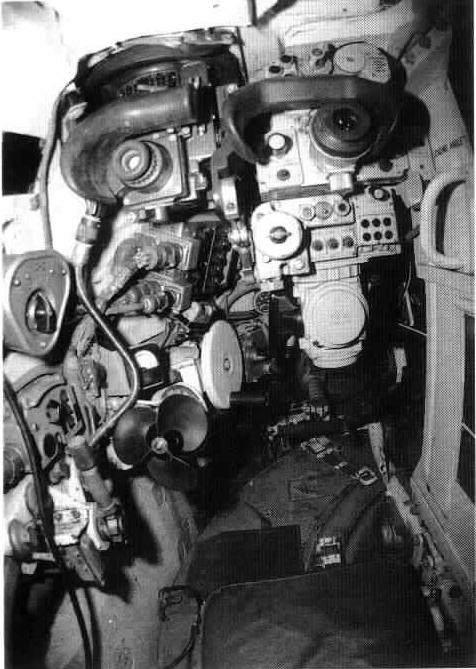

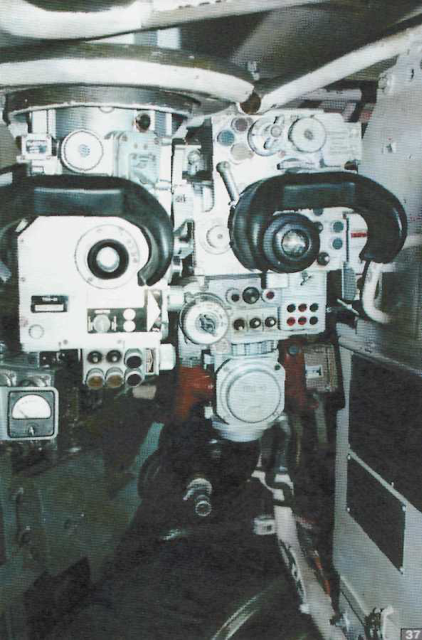

Even though the commander in a T-72 does not have the abundance of space that an M60A1 commander may be accustomed to, it meets all ergonomic requirements and it is a sizable improvement over the T-54 and T-62 as much of the equipment attached to the wall of the commander's station (like the bulky radio) have been moved forward so as to free up more space for his shoulders, as shown in the many photos featured in this article. This additional space allows the commander to freely service the coaxial machine gun and operate the radio. The gunner of the T-72 has less space since the sights and gunnery controls occupy all of the room in front of him. Both crew members have more than enough legroom thanks to the seating arrangement where each man has his own half of the turret. Based on the diameter of the autoloader carousel (1,800mm) and the location of the seats, the length of both the commander's station and the gunner's station is 1,150mm (measured from the backrest of their seats) which is more than the 1,000mm figure shown in the drawing above.

Overall, the T-72 definitely offers more space for the commander than a T-55 and the gunner gets more legroom, despite the what the figures given in "Human Factors and Scientific Progress in Tank Building" imply. It is likely that such figures are calculated by using a simplified model of human dimensions and internal tank dimensions which would not accurately reflect the actual conditions of the crew. In fact, the drawing shown below clearly illustrates why it would be quite impossible for the commander's station in a T-55 to be more spacious than in a T-72.

The internal volume and the distribution of volumes did not change throughout the entire evolution of the T-72 series from the original "Ural" to the T-72B. According to the book "Боевые Машины Уралвагонзавода: Танк Т-72" published by the Uralvagonzavod Production Association, the fighting compartment has a volume of 5.9 cubic meters, the driver's compartment has a volume of 2.0 cubic meters and the engine compartment has 3.1 cubic meters of volume, for a total internal volume of 11.0 cubic meters. This information is repeated in a media presentation from the TASS news agency and the engine compartment volume is corroborated by various journal articles regarding the volumetric efficiency of various powertrains. According to the journal article "Объемно-Массовый Анализ Защиты Серийных Танков", the volume of the T-72B turret above the turret ring is 1.7 cubic meters, the volume of the hull is 9.3 cubic meters, and the total is 11.0 cubic meters. From this, it can be seen that the fighting compartment can be divided into the 1.7 cubic meters in the turret (28.8%) and the 4.2 cubic meters in the hull (71.2%).

For comparison, the fighting compartment volume of the T-54/55 is 8.05 cubic meters, the fighting compartment volume of a T-62 is 9.23 cubic meters, the fighting compartment of the M47 Patton has a volume of 9.06 cubic meters, the M48 Patton has a fighting compartment volume of 10.48 cubic meters, and the volume of the M60A1 fighting compartment is 11.17 cubic meters. An especially noteworthy subject for a comparison is the Leopard 2A4, which has a fighting compartment volume of 10.1 cubic meters - less than an M48, which also had a smaller 90mm gun that took up less space.

The turret ring diameter of the T-72 is smaller than the turret ring diameter of the Leopard 2 (1,980mm), the Chieftain (2,159mm) and the M1 Abrams (2,159mm). Another factor behind the smaller internal volume of the turret of the T-72 - aside from the fact that it is built to accommodate only two crewmen instead of three - is the teardrop geometry which maximizes the frontal protection of the turret with minimal armour mass.

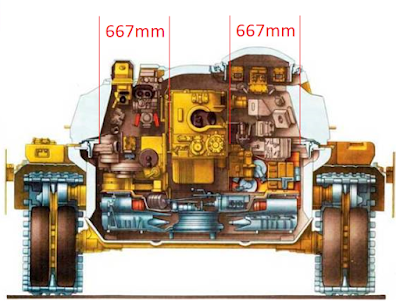

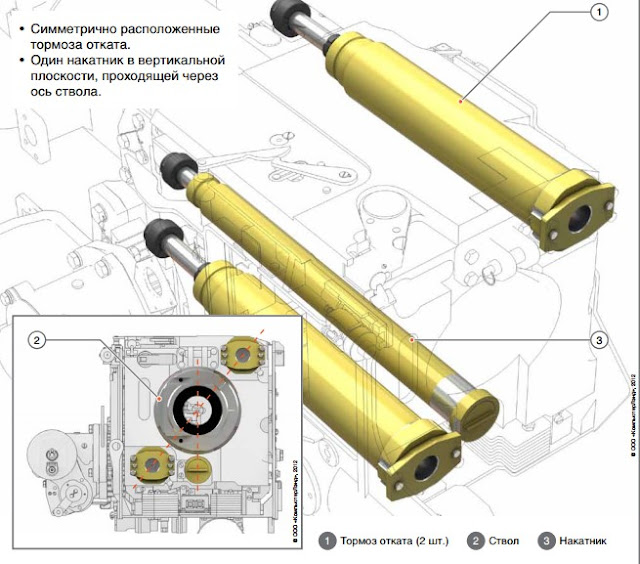

However, the actual available crew space inside the T-72 turret is increased thanks to the compactness of the 125mm D-81T gun. When measured at the widest point of its gun cradle and fixed recoil guard, the width of the gun is only 600mm. For comparison, the width of the Rh 120 smoothbore gun measured across the recoil guards is 660mm, according to data given by Dipl-Ing Rolf Hilmes in a seminar. Additionally, a measurement of the M68 gun on display at the Museum of Polish Military Technology showed that the width across the recoil guards is 672mm. The width disparity in favour of the T-72 translates to increased room for the crew in the turret. Coupled with the wide 1,934mm internal turret ring diameter of the T-72, it turns out that the maximum width of the gunner's and commander's stations is 667mm.

The vast majority of the Soviet Army's T-72 tanks up until 1979 was a T-72 Ural-1 model of some type, and this is instantly obvious when we examine the production record of the T-72: the production volume at Nizhny Tagil in 1975 and 1976 alone was 700 units and 1,017 units respectively, whereas only 250 units were released during the entire production run of the original T-72 Ural model from 1973 to 1974.

Since 1977, the T-72 Ural-1 already began to be produced with a new turret with a "Kvartz" non-metallic filler. This turret was standard for the T-72A (Object 172M-1) and became associated with it. As such, there were at least two types of T-72 Ural-1 tanks with major differences. The transition of the T-72A to the T-72B was similarly difficult to track. The T-72B was created out of the "Improved T-72A" project, and such tanks entered service as T-72A tanks years before the T-72B itself was officially adopted. According to Alexey Khlopotov, the 172.10.077SB turret commonly associated with the T-72B entered production in September 1982 and the T-72A began to receive these turrets in 1983 together with a new hull and a new upper glacis armour design. Other improvements such as the V-84 engine would be installed as late as 1984, further blurring the line between the latest T-72A models and the T-72B1. These late model T-72A tanks have the external appearance of a T-72B, but are not actual T-72B tanks (Object 184). Without going into very much detail, we can condense the evolution of the T-72 tank into a few main models.

Object 172M (T-72 Ural) 1973-1974

The original T-72 model with a monolithic cast steel turret and optical coincidence rangefinder-based sighting system. The IR spotlight was originally located on the left side of the cannon like the T-64A, but it was relocated to the right side in 1974 in order to improve driver safety.

Object 172M1 (T-72 Ural-1) 1975-1979

In this model, the "Gill" armour panels on the side of the hull from the T-72 Ural (originally from the T-64) were replaced with conventional side skirts sometime in the later half of its production run. The optical coincidence rangefinder-based sighting system was replaced by a laser rangefinder-based version sometime during the production run, at an unknown point. Modified turrets lacking the protrusion for the second optic port for the coincidence rangefinder were devised for these variants. The tank also began to receive a thermal shroud on the gun barrel in 1975.

Object 172M-1 (T-72A) 1979-1983

In 1976, the UKBTM design bureau was instructed by the Ministry of Defence to carry out a comprehensive modernization of the T-72 in order to increase its combat and operational characteristics. This work concluded with the adoption of the T-72A into the Soviet Army in 1979. Almost everything was changed; the tank had a revised hull armour and a new turret with a composite filler was implemented, the D-81TM cannon was installed, the 902A "Tucha" smoke grenade system was added, a new convoy light with a numerical display was installed, and more.

Object 184 (T-72B) 1985

Second serious upgrade of the T-72. The new tank featured completely revised hull and turret armour, a new autoloader, a guided missile firing capability, a new cannon, a new engine, new sighting systems, and more.

Object 184-1 (T-72B1) 1985

Simplified T-72B variant without the missile firing capability and with the original Ural autoloader. This aspect of the T-72B1 is examined later on in the article, in the section on the autoloader.

The T-72B itself was subject to a modernization project, initiated by the decree No. 741-208 of the USSR Council of Ministers on the 19th of June 1986. The "Improved T-72B" project, under the Object 188 index, entered service in 1992 as the T-90.

Again, it must be stressed that this is only a very basic list of variants. It is unwise to generalize with regards to the T-72, as the model designation sometimes does not reveal the full story.

Table of Contents

- Ergonomics

- Commander's Station

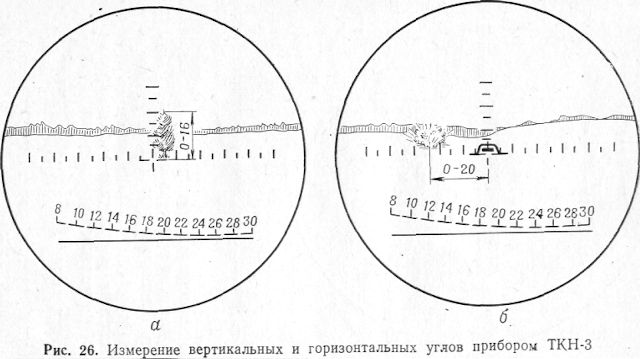

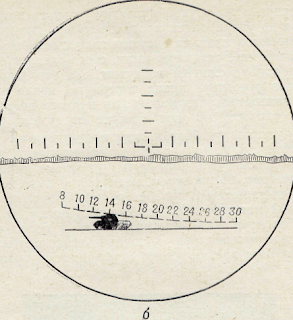

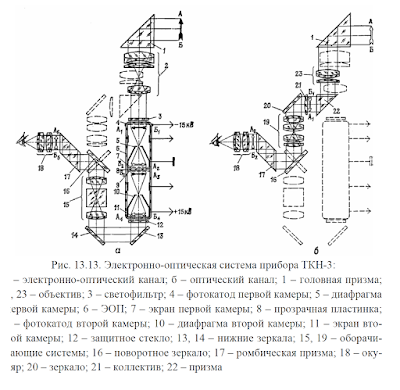

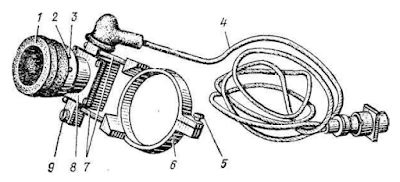

- TKN-3M

- Commander's Fire Controls

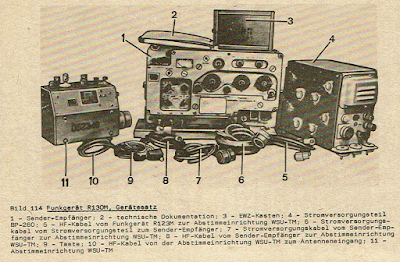

- Communications

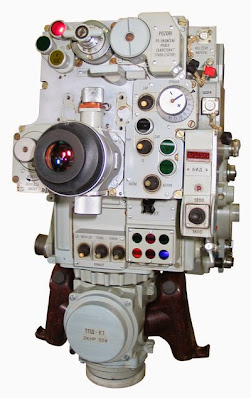

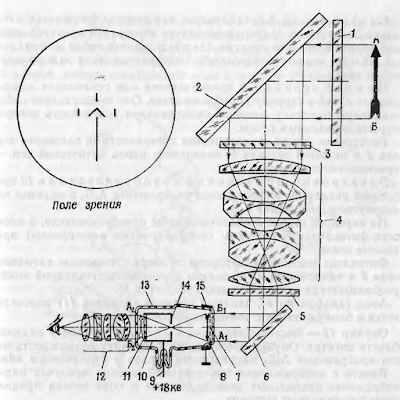

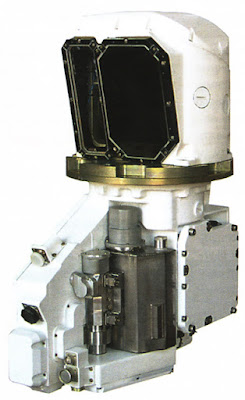

- Gunner's Station

- Sighting Complexes

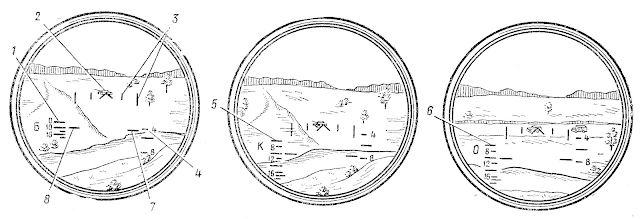

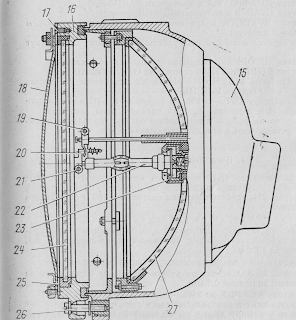

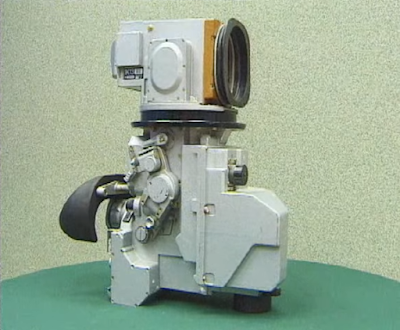

- TPD-2-49

- 1A40, 1A40-1

- Auxiliary Sights

- TPN-1-49-23

- TPN3-49

- 1K13-49

- 1A40-4 Sosna-U

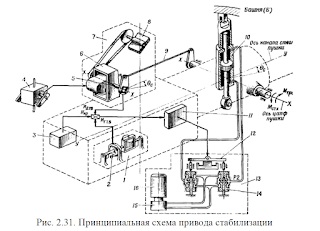

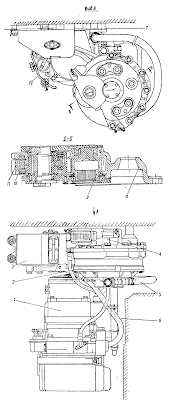

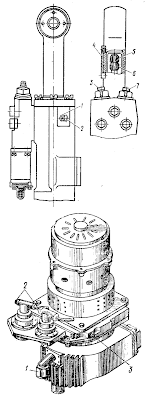

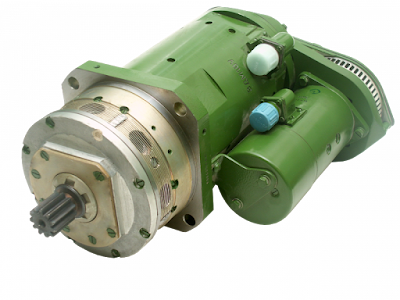

- Stabilizers

- 2E28M "Sireneviy"

- 2E42-2 "Zhasmin"

- 2E42-4

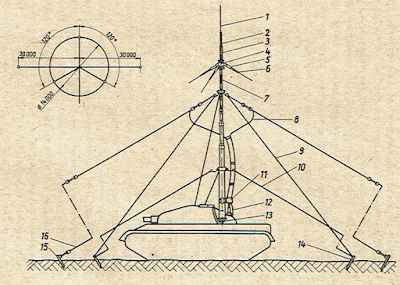

- Meteorological Mast

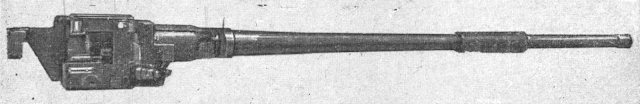

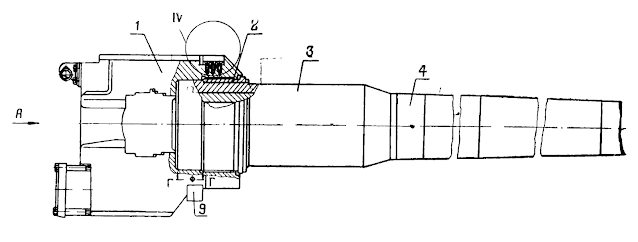

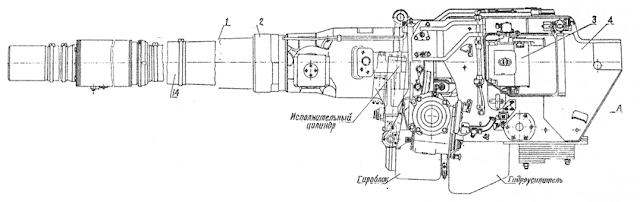

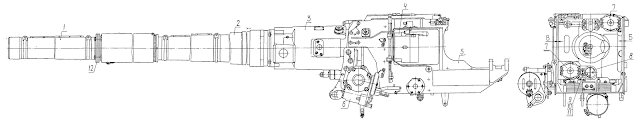

- D-81T Cannon

- 2A26M-2

- 2A46

- 2A46M

- 2A46M-5

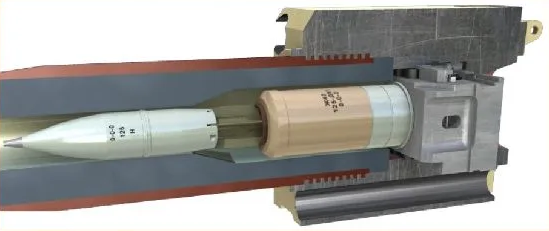

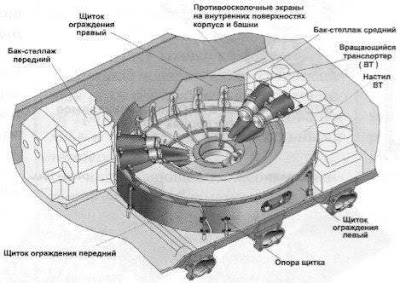

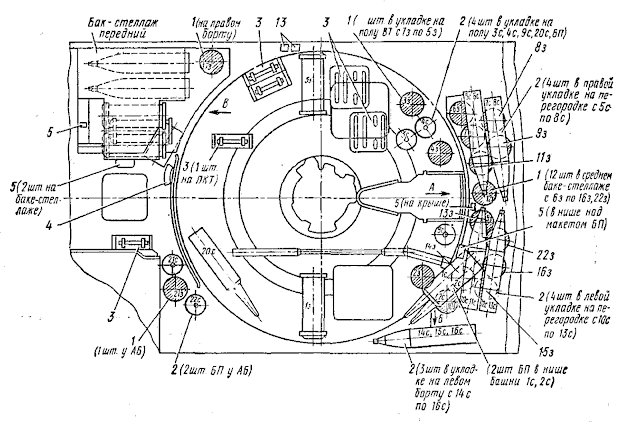

- Ammunition Stowage

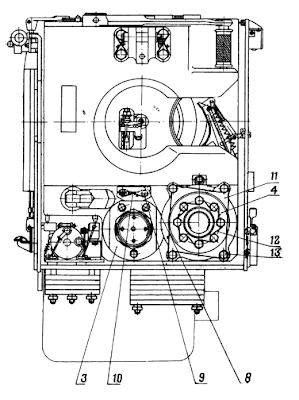

- Autoloader

- Loose Stowage

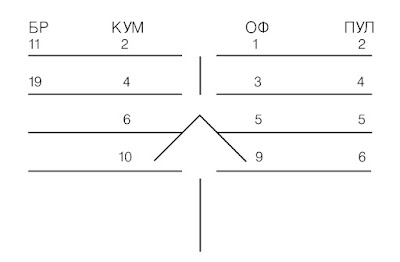

- Ammunition

- HE-Frag

- HEAT

- APFSDS

- PKMT Coaxial Machine Gun

- NSVT Anti-Aircraft Machine Gun

- Storage

- Escape Hatch

- Driver's Station

Due to length restrictions, this article has been divided into two parts. Part two is available here.

ERGONOMICS

In terms of ergonomic design, the T-72 is similar to the T-64, greatly superior to the T-62 and T-55, and broadly on par with many contemporary tanks. This is despite the extremely low height of the tank even compared to the T-62 and T-55, and the simple reason is that the use of an autoloader eliminated the need to allocate enough vertical space for a human loader to stand inside the tank.

The reduction to a three-man crew also enabled a more spacious turret crew layout to be implemented where the gunner and commander occupied their own halves of the turret, and the amount of space for the driver also increased. If we refer to this diagram from "Human Factors and Scientific Progress in Tank Building" by M.N. Tikhonov and I.D. Kudrin courtesy of Peter Samsonov, it is seen that the commander of a T-72 has 0.615 cubic meters of space, the gunner has 0.495 cubic meters of space and the driver has 0.864 cubic meters of space. However, the commander of a T-72 apparently has much less space compared to a T-55 commander (0.828 cubic meters), but this is obviously not possible. For one, the commander in a T-55 has to wrap his legs around the gunner seated in front of him because there is simply not enough legroom and the breech guard squeezes him against the turret wall where the radio is located. It is the exact opposite for the T-72. As the commander's station in the T-72 is completely separated from the gunner's station, there is nothing in front of him below chest level, and as a result, he has an abundance of legroom and sufficient headroom is guaranteed. It is perfectly possible for exceptionally tall people to command a T-72 without any ergonomic issues, and the commander can stretch his legs out as far as he desires even when the turret rotates. The difference of 0.1 cubic meters between the T-72 and the T-64A is also highly suspect, given that the two tanks are so similar.

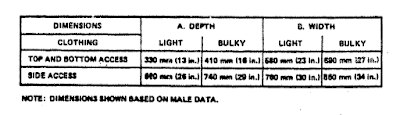

According to the article "Elements of Tank Design" by Gerald A. Halbert published in the November-December 1983 issue of ARMOR magazine, a seated man needs 0.4 cubic meters of space while wearing an NBC suit, a loader needs 0.8 cubic meters of space, and a driver needs 0.6 cubic meters of space. Halbert states that an additional 10% of space is needed for habitability and essential movement, so in actuality, a seated man wearing an NBC suit requires 0.44 cubic meters, a loader needs 0.88 cubic meters, and a driver needs 0.66 cubic meters. From this, it can be seen that the internal space provided for the T-72 commander greatly exceeds the ergonomic requirements for a seated man and the space provided for the gunner is still comfortably in excess of the requirements. The space provided for the driver of the T-72 also greatly exceeds the requirements. Furthermore, the rational and efficient layout of the controls and equipment in the tank facilitate crew comfort and ease of operation to a degree that cannot be expressed plainly in terms of volume.

In terms of dimensions, the hatches for all crew members would meet the minimum U.S Army human engineering requirements for a rectangular hatch size needed to accommodate a 95th percentile U.S male wearing light clothing, which is 13 x 23 inches (330 x 580 mm), as shown in the table below. These figures are sourced from the military standards document "Military Standard Human Engineering Design Criteria For Military Systems, Equipment And Facilities", MIL-STD-1472D.

However, given that none of the hatches are rectangular, but either have rounded corners (driver's hatch) or are semicircular, these requirements are not directly applicable. In fact, there is no standard for semicircular hatches, only oval and circular hatches, so there is no way to properly check the adequacy of the T-72 hatches. With that in mind, the hatches on the T-72 would probably not meet the minimum size for personnel wearing heavy clothing (NBC suit, winter clothes), but in fairness, virtually all tanks were designed only with light clothing in mind. On a Chieftain, the driver's rectangular hatch measures 381x540mm (15x21.25"), while the commander's oval hatch has a 508mm (20") maximum diameter, and the loader's rectangular hatch measures 508x432mm (20x17"). None of them meet U.S requirements for bulky clothing.

This was also true of newer tanks such as the Abrams series. A 1992 report by the U.S Army Biomedical Research & Development Laboratory, "Evaluation of Ventilation Inside Armored Vehicles", states that the loader's hatch is 23 inches in diameter (actual diameter is 22.5 inches). This is far felow the minimum requirement for circular hatches of 30 inches. The commander's hatch was measured to be 21.5 inches wide and 18 inches in length. This also falls short of the required size of oval hatches.

When taking into account the major differences in the anthropometric data between the conscription age men of the USSR and the enlisted personnel of fighting age in the U.S military, the hatches of the T-72 are of a favourable size. A 95th percentile American ground forces serviceman had a weight of 91.5 kg based on studies in 1966 and in 1977 with large sample sizes of USMC and U.S Army personnel, whereas the 95th percentile Soviet young adult male (conscription age) had a weight of 81.57 kg according to the USSR Anthropometric Atlas, 1977. U.S Army tankers were, and still are, recruited to a 95th percentile standard with a 183cm (6'1") official height limit. Soviet tank crews were recruited to a 50th percentile (average), standard, with a 175cm official height limit.

Keeping in mind that the 95th percentile for Soviet men is not the same as the 95th percentile for U.S men, and that smaller men were usually recruited for tank crews, the hatches on the T-72 were not only of an ideal size for a Soviet tank crew in light clothing, but were even adequate for winter clothing, whereas the same could not be said for U.S tanks.

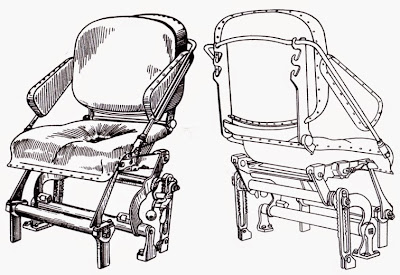

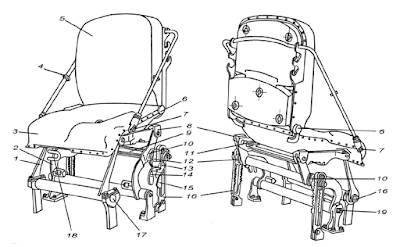

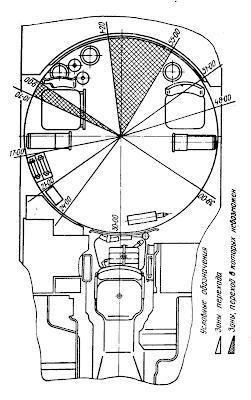

According to Sergey Suvorov, the use of an carousel-type autoloader in the T-72 as opposed to a basket-type autoloader as in the T-64 reduced the vertical space in the tank by around 25 cm. However, the height of the crew compartment in the turret was still more than sufficient, as the crew members are seated at all times when performing their duties. In the T-72, the seats for both the commander and gunner are only a short distance above the tallest point of the false floor of the turret so both crew members sit with their legs outstretched. The gunner's seat is fixed at a height of 150mm above the false floor, and the commander's seat has a variable height. This matched the minimum seat height figure of 150mm used as a reference in Soviet tank ergonomics design textbooks. Referring to the drawing below, it can be seen that the seated height of an average man wearing a tankers' uniform with a standard Soviet tankers' helmet is 1,050mm including a seat with a height of 150mm. The height of the hull and turret of the tank is 1,730mm (excluding ground clearance), and the maximum height of the AZ autoloader carousel is 450mm. Therefore, the internal height in the fighting compartment of the turret after subtracting the thickness of the turret roof and anti-radiation lining is up to 1,200mm. The commander's cupola extends above the turret roof, so in actuality, the vertical space allocated to the commander significantly exceeds this figure, but on the other hand, the turret roof over the gunner's station is sloped which reduces the gunner's headroom by a few inches. From this, it is clear that even a man of extremely tall stature would be able to fit in the commander's station and the gunner's station would still easily accommodate a man of average height.

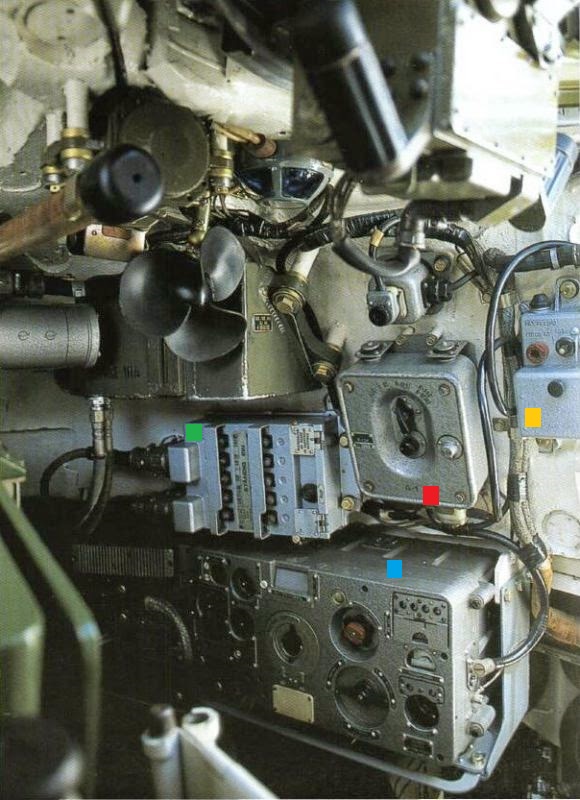

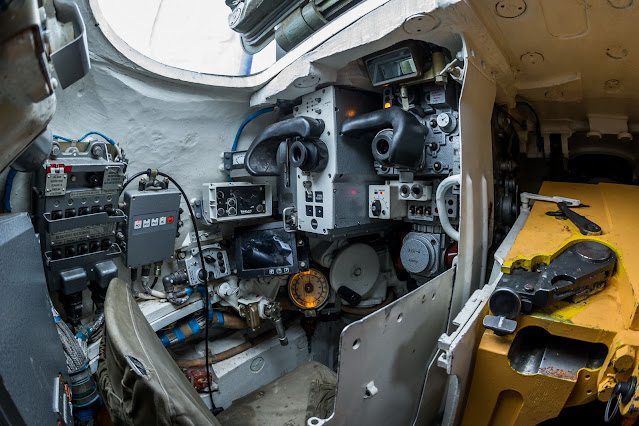

Even though the commander in a T-72 does not have the abundance of space that an M60A1 commander may be accustomed to, it meets all ergonomic requirements and it is a sizable improvement over the T-54 and T-62 as much of the equipment attached to the wall of the commander's station (like the bulky radio) have been moved forward so as to free up more space for his shoulders, as shown in the many photos featured in this article. This additional space allows the commander to freely service the coaxial machine gun and operate the radio. The gunner of the T-72 has less space since the sights and gunnery controls occupy all of the room in front of him. Both crew members have more than enough legroom thanks to the seating arrangement where each man has his own half of the turret. Based on the diameter of the autoloader carousel (1,800mm) and the location of the seats, the length of both the commander's station and the gunner's station is 1,150mm (measured from the backrest of their seats) which is more than the 1,000mm figure shown in the drawing above.

Overall, the T-72 definitely offers more space for the commander than a T-55 and the gunner gets more legroom, despite the what the figures given in "Human Factors and Scientific Progress in Tank Building" imply. It is likely that such figures are calculated by using a simplified model of human dimensions and internal tank dimensions which would not accurately reflect the actual conditions of the crew. In fact, the drawing shown below clearly illustrates why it would be quite impossible for the commander's station in a T-55 to be more spacious than in a T-72.

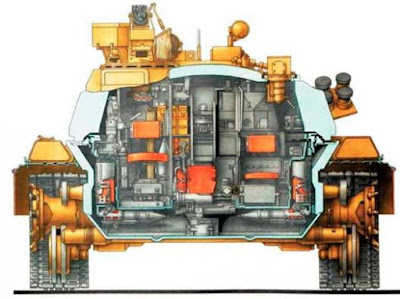

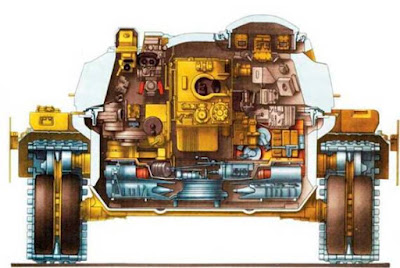

The internal volume and the distribution of volumes did not change throughout the entire evolution of the T-72 series from the original "Ural" to the T-72B. According to the book "Боевые Машины Уралвагонзавода: Танк Т-72" published by the Uralvagonzavod Production Association, the fighting compartment has a volume of 5.9 cubic meters, the driver's compartment has a volume of 2.0 cubic meters and the engine compartment has 3.1 cubic meters of volume, for a total internal volume of 11.0 cubic meters. This information is repeated in a media presentation from the TASS news agency and the engine compartment volume is corroborated by various journal articles regarding the volumetric efficiency of various powertrains. According to the journal article "Объемно-Массовый Анализ Защиты Серийных Танков", the volume of the T-72B turret above the turret ring is 1.7 cubic meters, the volume of the hull is 9.3 cubic meters, and the total is 11.0 cubic meters. From this, it can be seen that the fighting compartment can be divided into the 1.7 cubic meters in the turret (28.8%) and the 4.2 cubic meters in the hull (71.2%).

Other figures published for the internal volume of the T-72 are incorrect, like in the article "Основы теории и история развития компоновки танка" ("Fundamentals of the theory and history of the development of the tank layout") by Vasily Chobitok where it is stated that total internal volume of the T-72 is 11.8 cubic meters.

For comparison, the fighting compartment volume of the T-54/55 is 8.05 cubic meters, the fighting compartment volume of a T-62 is 9.23 cubic meters, the fighting compartment of the M47 Patton has a volume of 9.06 cubic meters, the M48 Patton has a fighting compartment volume of 10.48 cubic meters, and the volume of the M60A1 fighting compartment is 11.17 cubic meters. An especially noteworthy subject for a comparison is the Leopard 2A4, which has a fighting compartment volume of 10.1 cubic meters - less than an M48, which also had a smaller 90mm gun that took up less space.

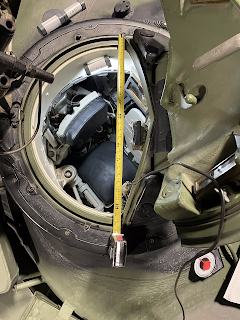

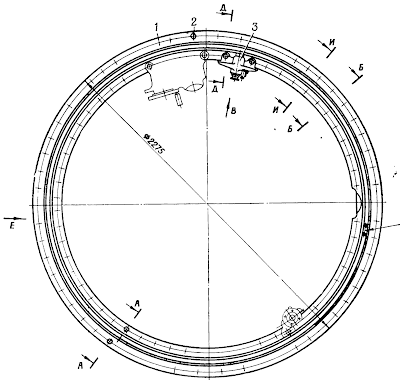

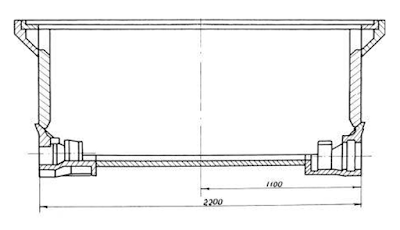

The diameter of the turret ring hole cut into the hull roof is 2,162mm. The external diameter of the turret ring is 2,275mm, the bearing pitch diameter is 2,116mm, and the internal diameter of the turret ring is 1,934mm. All numbers given are from technical drawings.

Internally, the width of the turret is approximately equal to the diameter of the turret ring, with the area over the crew seats being wider than the turret ring itself due to the thinner side and rear armour, thus forming a shelf which is lined with anti-radiation material. With the partial removal of the lining on the T-72B3, the free space is used to install some electronic equipment instead.

The width of the lower part of the fighting compartment is equal to the internal width of the hull, which is around 1,940mm wide as calculated by subtracting side hull armour (80mm) and anti-radiation lining (50mm) from the external width of hull (2,200mm). The actual width at the fighting compartment is larger, as the anti-radiation lining is thinned down to an inch (25mm) and curved to conform to the diameter of the autoloader carousel. Owing to the increased hull width, the internal width is 100mm larger than the T-54 and T-62, which did not have an anti-radiation lining, and it is 190mm larger than the T-55(A), which did. For comparison, the Leopard 2 turret basket has a diameter of 1,990mm. Taking into account the fact that the anti-radiation liner is curved following the contour of the carousel, the fighting compartment diameter of the T-72 is 1,990mm, identical to the Leopard 2. The true fighting compartment diameter, as measured according to the carousel top cover diameter and turret ring diameter, is 1,940mm. Taking the carousel top cover as the surrogate of a conventional rotating turret floor, it could be said that the T-72 has the widest turret floor among both domestic and foreign contemporaries. This is the main factor that made it possible for the turret crew to be seated with abundant legroom.

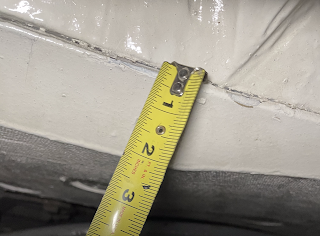

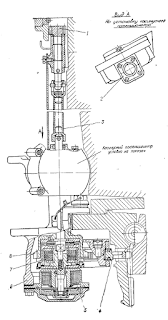

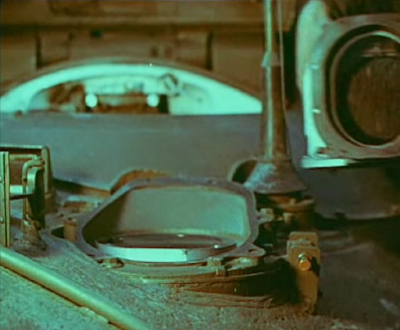

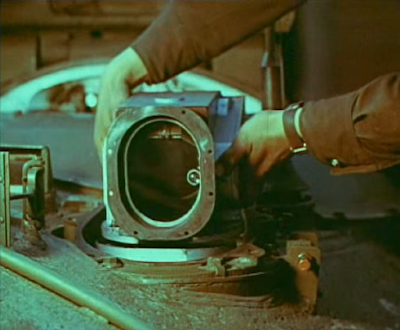

The difference between the diameter of the carousel top cover and the diameter of hole in the turret roof, very close to the bearing pitch diameter of 2,116mm, is very large, as the image below shows.

This is more than the T-64 and T-64A which has the crew seated in a turret cabin suspended from the turret ring, which separates the crew from the turret ring by a radius equivalent to the thickness of the ring of ammunition in the autoloader, reducing the diameter of the crew space to only 1,590mm or less. Maximizing the width of the lower part of the fighting compartment is considered less important than maximizing the width of the upper part because the legs of the crew occupy less space than their shoulders (average human shoulder width: 450mm, average hip width: 350mm), not to mention that some elbow room is needed for the crew to operate the equipment in their respective stations. Even so, the additional width provided by the design of the T-72 autoloader is still a noticeable benefit. One major reason is that the turret is low enough that the turret crew will have at least part of their torsos below the level of the turret ring, and the gunner has his elbows below the level of the turret ring practically at all times while carrying out his duties.

For instance, it can be seen in the images below (T-80B left, T-80U right) that, while the width of the crew stations is the same as the T-72 aside from the constrained diameter imposed by the cabin, and is quite generous, the space taken up by the cabin limits the size of the seats, particularly in the case of the T-80U where the cuts make the width and length constraints apparent.

The turret ring diameter of the T-72 is smaller than the turret ring diameter of the Leopard 2 (1,980mm), the Chieftain (2,159mm) and the M1 Abrams (2,159mm). Another factor behind the smaller internal volume of the turret of the T-72 - aside from the fact that it is built to accommodate only two crewmen instead of three - is the teardrop geometry which maximizes the frontal protection of the turret with minimal armour mass.

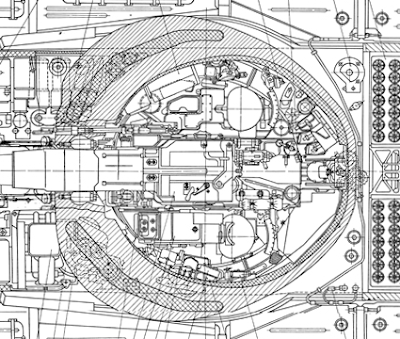

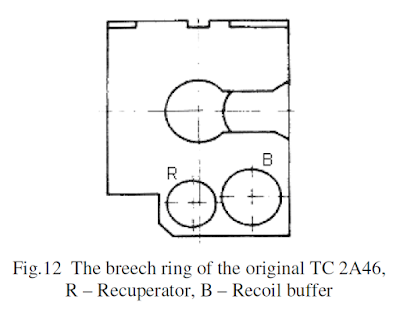

However, the actual available crew space inside the T-72 turret is increased thanks to the compactness of the 125mm D-81T gun. When measured at the widest point of its gun cradle and fixed recoil guard, the width of the gun is only 600mm. For comparison, the width of the Rh 120 smoothbore gun measured across the recoil guards is 660mm, according to data given by Dipl-Ing Rolf Hilmes in a seminar. Additionally, a measurement of the M68 gun on display at the Museum of Polish Military Technology showed that the width across the recoil guards is 672mm. The width disparity in favour of the T-72 translates to increased room for the crew in the turret. Coupled with the wide 1,934mm internal turret ring diameter of the T-72, it turns out that the maximum width of the gunner's and commander's stations is 667mm.

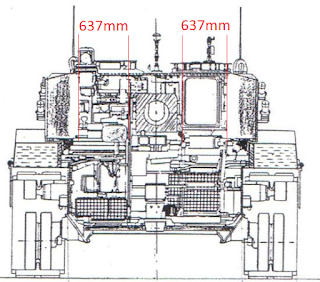

For the Leopard 2, the turret ring diameter is not indicative of the internal turret width because the side armour over the crew compartment (310mm in thickness) overhangs the turret ring by a significant amount and takes up additional internal space. After subtracting the overhang, the internal width of the turret coincidentally turns out to be 1,934mm - the exact same as the T-72. After subtracting the width of the Rh 120 gun cradle, the maximum width of the two halves of the turret occupied by the crew members is around 637mm.

This difference is illustrated in the two drawings below. Note that in the T-72 cross section, the proportions of the various internal components and the turret walls are not accurate. The image is used only to demonstrate the points of measurement.

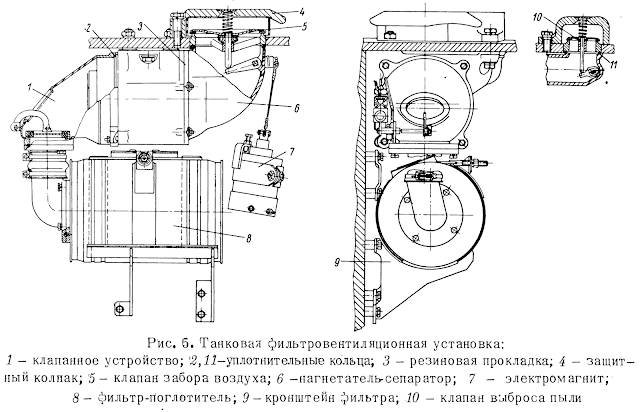

Besides the space allocated to the crew, there are other factors affect the comfort of the crew such as thermal regulation and ventilation. For collective ventilation, the T-72 features an FVU (filter-ventilator unit) which serves as a regular blower for general ventilation of the crew compartment and a filtration unit with an overpressure generator, driven by a supercharger. As a filtration unit, the FVU performs both cyclonic separation of coarse particles and fine filtration via HEPA elements. The purified air is then accelerated by a supercharger to ensure a rapid flow of air, sufficient to generate an internal overpressure. As it is a filter element and not a mechanical separator like the supercharger fan, the FVU filter needs to be checked after every 6,600-7,000 km of use.

This difference is illustrated in the two drawings below. Note that in the T-72 cross section, the proportions of the various internal components and the turret walls are not accurate. The image is used only to demonstrate the points of measurement.

It is important to keep in mind that the actual crew space width is slightly less, because there are additional safety guards in both tanks. Still, it can be seen that the T-72 is not inferior to more modern counterpart in critical dimensions for crew ergonomics. According to the REO-SV-80 guidelines (Guidelines for the ergonomic provisions of the creation of military equipment for the ground forces), the crew station width should be 580mm wide for a tank gunner and 600mm wide for a tank commander. The T-72 conforms to these guidelines.

The AZ autoloader used in the T-72 permitted free movement between the fighting compartment and the driver's compartment as there is a gap of approximately 500mm between the carousel and the hull ceiling, creating a crawlspace of sufficient size for an average man. The crawlspace is only inaccessible if the turret is turned to face the direct rear, thus positioning the autoloader elevator mechanism over the gap. It is also blocked if the commander's seat adjustment mechanism is positioned directly over the gap. Crawling to and from the driver position is possible when the turret is facing forward, but very challenging because of the multitude of gun stabilizer components hanging below the 125mm gun, constricting the crawlspace size. When the tank has its turret turned to the travel position or has its turret oriented forwards or to the sides, which highly likely in combat, there is sufficient space that a wounded driver can be evacuated through the turret by either of the two other crew members, or conversely (and more importantly), the crew members in the fighting compartment can crawl into the hull to access the escape hatch in the belly.

Moreover, if the tank is driven into a deep water-filled ditch, the crawlspace gives the driver an avenue of escape as the driver's compartment is filled with water or at least provides enough room for the driver to keep his head above water.

VENTILATION

Besides the space allocated to the crew, there are other factors affect the comfort of the crew such as thermal regulation and ventilation. For collective ventilation, the T-72 features an FVU (filter-ventilator unit) which serves as a regular blower for general ventilation of the crew compartment and a filtration unit with an overpressure generator, driven by a supercharger. As a filtration unit, the FVU performs both cyclonic separation of coarse particles and fine filtration via HEPA elements. The purified air is then accelerated by a supercharger to ensure a rapid flow of air, sufficient to generate an internal overpressure. As it is a filter element and not a mechanical separator like the supercharger fan, the FVU filter needs to be checked after every 6,600-7,000 km of use.

Additionally, the supercharger of the ventilation unit can be used while bypassing the filtration system in an auxiliary mode by turning it on manually. This can be done to enhance airflow in the crew compartment in hot weather. The supercharger is also connected to the firing circuit of the main gun and coaxial machine gun. When either the main gun or the machine gun is fired, the supercharger turns on automatically to increase air circulation in the crew compartment, helping to evacuate the fumes from the weapons so that an excessive concentration of fumes does not accumulate during sustained fire. When operating the coaxial machine gun or main gun manually due to a failure in the electrical firing circuits, the technical manual for the T-72 recommends turning on the supercharger manually before firing.

In recent tank models with a modernized autoloader, including the T-90A and T-72B3, the spent casing ejection port also briefly opens after a shot is fired from the main gun. Combined with the automatic activation of the supercharger, a reduction in the concentration of propellant fumes in the tank is achieved.

For local ventilation, each crew member in the tank is provided with a DV-3 personal fan, a simple 5.2W fan running on the tank's 27V electrical system.

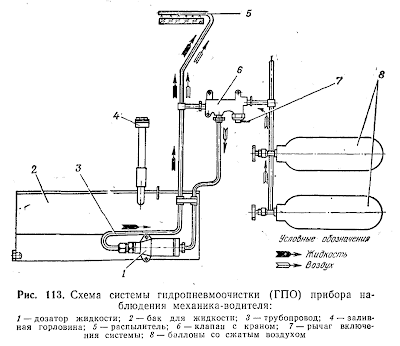

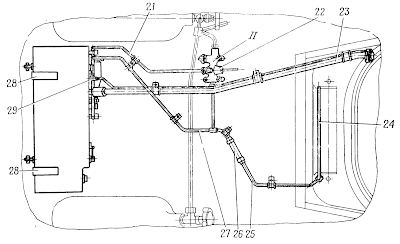

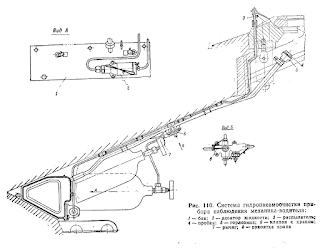

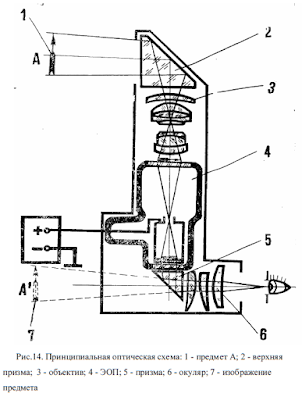

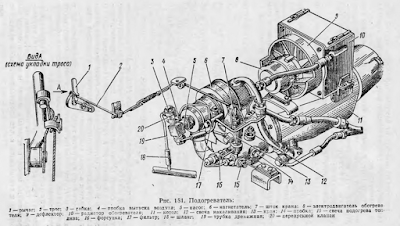

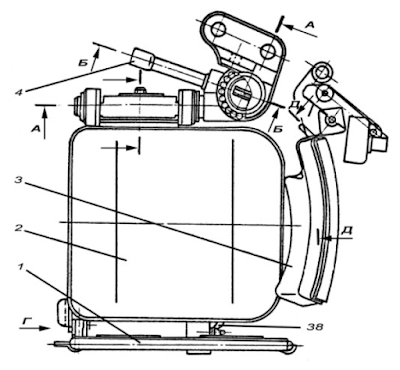

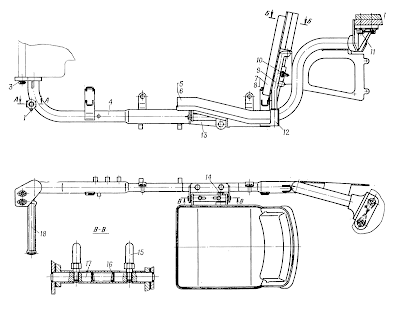

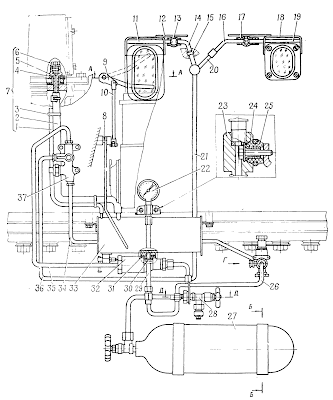

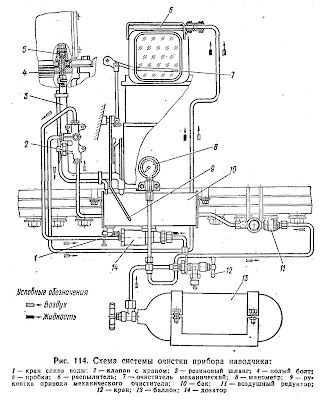

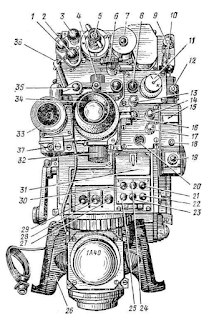

When the tank is driven in regions with a hot climate, ventilation for the crew is supplemented by opening the OPVT intake hole in the engine compartment bulkhead, allowing the engine to draw air from the crew compartment. The effect of doing so is that the ventilator is combined with the powerful draw of the radiator cooling fan to create a strong draft inside the crew compartment. At the same time, this can improve the purity of the air for the engine in dusty environments. When using this method of ventilation, the supercharger should be turned on, or at least one hatch should be ajar, or the snorkel mount hole in the gunner's hatch should be opened. The diagram below shows the OPVT intake hole and the pulley mechanism used to open it from the driver's compartment. When opened, air is drawn through the crew compartment into the engine compartment, past the rear end of the engine near its exhaust ducts, and out through the cooling fan outlet. Opening this intake hole does not come without its costs though, as doing so will slightly increase the pressure in the engine compartment, compromising the negative pressure inside the engine compartment which draws air through the radiators. In situations where cooling efficiency is critical, such as in extremely hot weather conditions, it is imperative that no loss of efficiency is introduced, to prevent the engine from overheating. In such circumstances, the crew is obliged to acquiesce to the needs of the tank rather than their own.

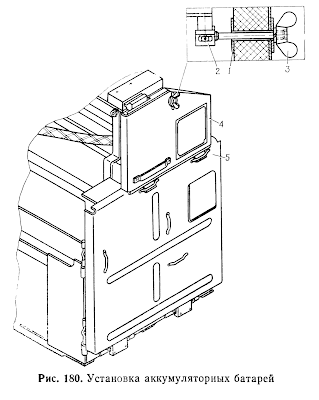

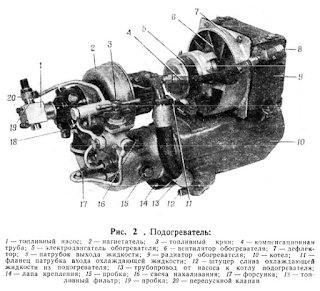

Besides a fairly good ventilation system, the T-72 also featured a heater, adapted from the heater in the T-64. The heater is a dual-purpose device designed to pre-heat the engine before starting it in ambient temperature conditions of 5°C or below when using diesel and kerosene fuel, or when operating at 20°C and below when using gasoline. It was also designed to provide heat to the fighting compartment of the tank via a built-in radiator when it is turned on during engine preheating. The heater is installed at the rear starboard corner of the fighting compartment, beneath the fighting compartment ventilator and next to the rear hull conformal fuel tank. The fuel consumption rate is no more than 9 liters per hour, and it can run continuously. The only limit on the duration of operation is the fuel supply.

The device generates heat by producing a jet of flame in a special boiler using any of the three fuel types specified for the T-72 - diesel, gasoline or kerosene. The boiler heats up the coolant (water), which is circulated around the engine and oil tanks in a closed loop by a boiler pump powered by an electric motor with a manual backup. The same electric motor also powers the air intake fan which supplies air to the boiler and powers the fuel pump which supplies fuel to the boiler. Exhaust gasses from the combustion chamber in the boiler are ejected out of the tank through an exhaust outlet on the side of the hull.

The device generates heat by producing a jet of flame in a special boiler using any of the three fuel types specified for the T-72 - diesel, gasoline or kerosene. The boiler heats up the coolant (water), which is circulated around the engine and oil tanks in a closed loop by a boiler pump powered by an electric motor with a manual backup. The same electric motor also powers the air intake fan which supplies air to the boiler and powers the fuel pump which supplies fuel to the boiler. Exhaust gasses from the combustion chamber in the boiler are ejected out of the tank through an exhaust outlet on the side of the hull.

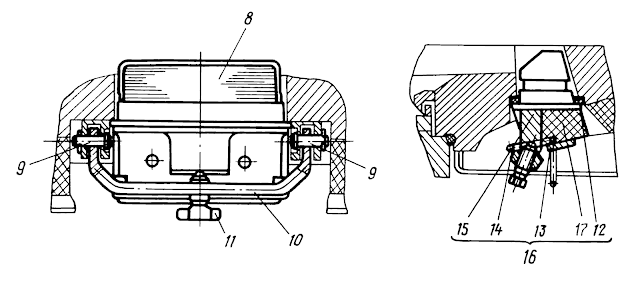

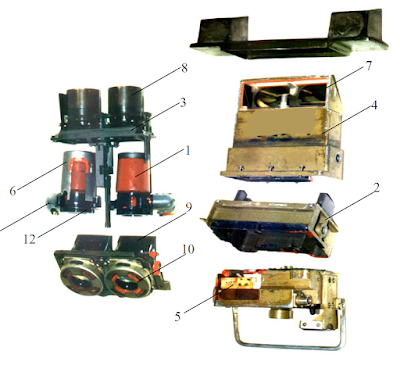

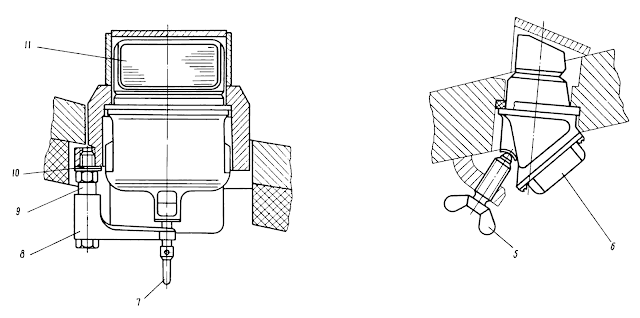

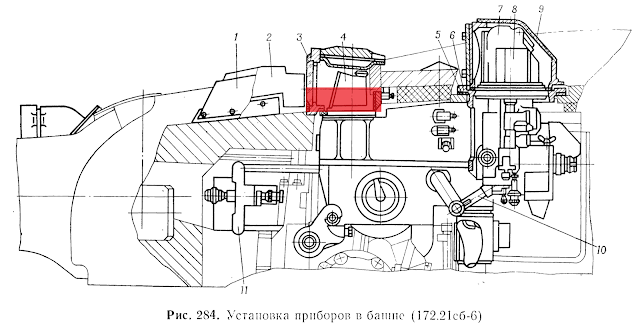

Heating for the fighting compartment of the tank is providing by a small tube radiator marked (9) in the drawing below which is heated with hot water from the boiler or from the engine. A fan, marked (6) in the photo below, blows air through the radiator to ensure that heated air circulates around the enclosed space of the tank fighting compartment more quickly. The heater fan is quite powerful, being driven by an MV-42 motor operating at a power of 175 W and turning at 3,500 RPM. Fans with the same motor are used in the ventilation exhaust fans in the T-10 heavy tank series. When using the heater while preheating the engine, the boiler pump of the heater is used to circulate hot water through the small radiator and the engine simultaneously. When using the heater with the engine running, the running engine heats up the circulating water which is pumped through the mini radiator under pressure from the main coolant pump, and heat for the crew is generated without using either the boiler or the boiler pump. To better appreciate the usefulness of this feature, it should be noted that on some tanks, heating for the fighting compartment is only provided by opening a flap in the engine compartment bulkhead to allow engine heat to enter which is a simple and dependable heating method but may also allow various noxious fumes to pollute the crew compartment. Heaters that depend on a boiler or electric element also tend to have very low reliability. This solution of using the tank's coolant with a mini-radiator, was an ingenious solution to the issue of reliable heating, which can be credited entirely to the original T-64 design.

When running, the boiler effectively turns the preheater into a hot plate, which can be used to heat ration tins and water.

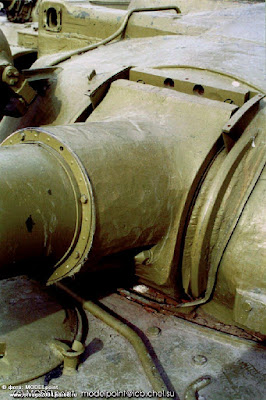

Since the heater is installed beneath the fighting compartment ventilator, the flow of air from the ventilator blower fan helps to circulate the hot air inside the tank. The heater unit is shown in the photo on the left below (photo originally shared on btvt.narod). The heater exhaust outlet is situated between the fourth and fifth roadwheels on the starboard side of the hull, as shown in the photo on the right below (photo credit to Thomas Voigt).

A serious design flaw of the heater was that dirt or snow could enter the exhaust outlet and cause a blockage despite the outgoing flow of exhaust gasses, and frequent cleaning is required as soot accumulates easily in the combustion chamber of the boiler. This was a chronic source of heater breakdowns, giving it the reputation of being high-maintenance and unreliable. On the other hand, the likelihood exists that much of the soot accumulation issue stems from the use of the heater with worn and discharged batteries, since the T-72 technical manual states that it is prohibited to use the heater when the master power is less than 22 V as this leads to rapid carbon formation on the walls of the heater.

A major advantage of the heater design is that the boiler does not need to be running to provide heat for the crew, as heat is supplied by the engine with the added bonus of somewhat contributing to the cooling of the engine. However, the system does not feature a temperature regulator as the heating element is not electric and the radiator fan motor has no speed control, so the fighting compartment heating system can only be either on or off using the toggle switch on the driver's instrument panel. The crew compartment is heated up at an accelerated rate while preheating the engine due to the large heat output of the boiler, and once the engine is started, heat for the crew compartment is sourced from the engine. The main disadvantage of the system is that heated air is not dispensed from vents at the individual crew stations like in a T-80.

Furthermore, the T-72 had a thick internal anti-radiation lining on the surfaces of the turret and hull. On the frontal cheeks of the turret where the armour was thickest, the lining was only 10-20mm thick as the armour itself provided good shielding from penetrating radiation such as gamma rays and neutrons, but on other parts of the tank including the sides, rear, and ceiling of the turret, the sides of the hull, and on the autoloader carousel cover, the anti-radiation lining was 45-50mm thick to compensate for the low thickness of armour. This lining was known as "Podboi". Beginning in 1983, an external anti-neutron cladding with a thickness of 50mm was added on the turret and hull surrounding the inhabited parts of the tank as a response to an announcement by U.S president Ronald Reagan in 1981 that the production of neutron bombs would be restarted. This cladding was known as "Nadboi". Both the internal lining and external cladding were made from a laminate of hydrogen-rich polyethylene (UHMWPE) and polyisobutylene sheets impregnated with lead.